|

August 18, 2012 - Well, I

didn't get my wish...I was hoping to get the second coat of

primer sprayed today, but the weather forecasters were

correct in their rain prediction. It started raining about

8AM this morning, and rained non-stop for around 4-1/2

hours. Therefore, there won't be any priming done today...or

tomorrow either, for that matter. Since primer tends to

absorb moisture, I need to give the truck a minimum of one

full day to dry out before thinking about doing any sanding

or spraying. So since I'd allocated

today as a day of working on my truck, but I can't, I

thought I'd head everyone off at the pass so-to-speak, and

spend the day putting this page together, to give you some

information about the paint and primer I'm using and the

equipment I'm spraying it with.

Fig. 01 - This shows my

bumpside fender with two coats of Rustoleum

rolled on. The orange-peel is evident, but would

have disappeared with a little wet-sanding. |

The Paint

By now I don't think there's

anyone online who hasn't heard of the infamous "$50 Paint

Job", a

moparts.org forum thread that has spread to virtually

every automotive-related forum online. (Do a Google search

for '$50 paint job' and you'll have enough reading to keep

you busy for weeks.) This thread describes how to use

readily-available Rustoleum paint and high-density foam

rollers to give a very nice paint job for very little

monetary investment. It's become a low-cost alternative for

folks who don't mind investing a little more time than

money, since a great deal of color sanding is required, or

who don't have the means or desire to invest in all the

equipment necessary to do a proper basecoat/clearcoat or

single-state urethane paint job. And while it's not a method

that should be used to paint a collectible car, it's

definitely something worth considering for a work or school

car, where a show-quality paint job isn't necessary or even

an option.

Back when I was working on

my truck in the shop, before I lost the shop, I'd read this

moparts thread, as well as many others on other automotive

forums, where people were using this method with pretty good

results. Although my shop did have a large single-stage air

compressor, it still didn't have the air output recommended

for an HVLP (high-volume low-pressure) paint gun. I could

probably have made it work, by not trying to paint the

entire truck in one setting...by painting a panel or two per

day...but I was still very intrigued by this Rustoleum

method, so I decided to give it a try on one fender of my

truck, just to see how it looked. I bought all the supplies

(primer, paint, sandpaper, etc.) and got started. I was

actually impressed with what I'd seen so far, though I only

made it halfway through the process on this one fender

before having to stop and move out of my shop and the truck

into storage.

Anyway, at the time, I'd

wanted to go with a very deep dark blue, but the color that

got mixed for me ended up being more of a purple-ish

blue...not at all what I had in mind. I told myself that

once I got back to work painting the truck, I'd get another

batch of Rustoleum mixed up in the proper dark blue.

Fig. 02 - My flat-black

choptop truck inspired me to go a step further

than a basic flat-black truck. I kept picturing

this truck low to the ground, with tinted

windows and custom rims....and a paint job

slightly different from the everyday flat black

that's been overused. |

But in the years since I

last worked on the truck, and especially in the past few

months since getting back to work on my truck, I'd been

starting to lean very heavily in another direction, another

'cheapo paint job' alternative. I really liked the look of

my flat-black choptop truck and wanted to do something

similar...and one of the more-popular flat-black

alternatives is an implement paint by John Deere, called

Blitz Black. This particular paint isn't flat, nor is it

semi-flat...it's sort of in the middle. It's more of a

satin/suede paint, manufactured for John Deere by Valspar,

and has a sheen to it a lot like what a new barbeque grill

might have. I like to think of it as 'flat black...with a

little attitude'.

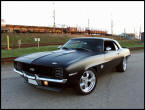

If you do a Google search for Blitz Black,

you'll have plenty to read about it (both pro and con) on

various websites. However, among the hotrod crowd it's

gotten very popular, due to it's ease of application and the

overall sheen that's left after it dries. And it's

what I've decided to do with my truck. Here are a couple

pictures I found online of vehicles painted with Blitz

Black, just to give you an idea of what it looks like. Fig.

03 even shows a bumpside truck with this paint:

Fig. 03 |

Fig. 04 |

Fig. 05 |

Fig. 06 |

Here are a links to read more about Blitz

Black:

So how am I going to apply the paint and

primer? Read on...

The Paint Gun

As mentioned earlier, I'm

building this truck outside in my driveway, out in front of

my little one-car garage. There is no 220V hookup in there

for an air compressor, so I was looking at either rolling

this stuff on with foam rollers (like the Rustoleum), or

trying to scrape together enough funds for a cheap 110V air

compressor and cheap HVLP gun from Harbor Freight, and just

spraying it on in small batches. However, I found an

alternative.

While doing some research

one night, I was reading on a VW forum [link]

about turbine HVLP spray guns. These setups don't need an

air compressor, since it just basically blows the air at

high speed, using the same motor as a vacuum cleaner, and

there is no need for oil or water filters, since there's no

oil in the turbine and no air is being compressed to

generate the moisture. You don't have to wait for a

compressor to 'catch up'...therefore they'll spray all day

long. These spray gun setups will handle automotive paints

just fine, according to those who have used them (though I

haven't yet read about anyone who has tried spraying

metallics through one). Now, just like any equipment, you

can get high-end versions of a turbine HVLP sprayer like

those offered by

TurbineProducts.com or the less expensive models like

several offered at Harbor Freight.

Here's the one I bought from Harbor

Freight and am using:

High Volume, Low Pressure

Spray Gun Kit

(link to Harbor Freight

listing)

Chicago Electric Power Tools

Item #44677

$129.99 |

|

Since this

HVLP gun might no longer be available from

Harbor Freight a few years in the future, and I

wanted to properly document what I'm using, I

did a screen-capture of the page where it's

listed on the HF website. If the direct link at

left becomes inactive or you get a page error,

CLICK HERE to view this screenshot. |

At first I tried the Buff Primer

recommended for the Blitz Black by John Deere, thinning it

with the JD thinner according to the instructions on the

primer can, and spraying onto a dented hood I got from a

local body shop. I was not at all impressed with the huge

amount of orange peel I got. Tried different settings on the

gun, but no improvements. Then I decided to try thinning it

out a bit more, and the orange peel problem was

significantly reduced, though still a bit more than I was

happy with. I should have tried thinning it a bit more, per

what I've been reading on the various forums, where they

recommend thinning the paint 10%-20% more than what's called

for on the can. If I had, I'd probably have been happier.

However, I then decided to try spraying

the Rustoleum primer I had, and was much happier with the

results, though there was still a small amount of orange

peel evident. Again, in retrospect, I really should have

tried thinning it out a bit more than called for on the can

for better results.

Anyway, I used two quarts

of Rustoleum primer on the cab and front sheetmetal and it

laid down very smooth, with hardly any orange peel at all.

Once it dries, and I'm able to add a second coat, I think

it'll sand down extremely smooth. However, when I mixed up

the Rustoleum primer to paint the box, I suddenly started

have spattering problems and much more orange peel. After

spraying about half the box, I stopped and went in and added

a little more mineral spirits to the mix, and the rest

sprayed out great...so it WAS simply a matter of not having

it thinned enough. When I go to spray the second coat of

primer on, I will definitely thin it out more, at least 10%

more than called for on the can (which is only 1 or 2 parts

to 10 parts primer). I also want to try a smaller tip. The

1.8 tip was installed when I got the gun and seeing as how

that's what's normally recommended, I left it in. However,

those on the forums who use their turbine sprayers suggest

using a smaller tip. So within the next week or so, when I

get ready to spray the second coat, I'll be doing some more

experimenting beforehand, trying a smaller tip and thinning

it out a bit more and will report back how it's working.

I think overall I'm going

to be very happy with this, especially considering the

minimal investment. There's just the learning curve where I

need to figure out the optimal settings, mixtures, etc. to

get the best results with the products I'm using. Once I get

it figured out, I just might have to write up a tutorial for

the tech section, describing what I found out and give some

overall impressions.

Stay tuned! |