|

|

|

|

|

Automatic Transmission Identification Guide

Reprinted from Car Craft 12-02 - Article and photos by Marko Radielovic |

|

|

|

|

This

article will take a good, hard look at Ford's offerings on the

slush-box front. Seeing as we don't know a heck of a lot about Ford

automatics, we abducted a variety of transmission experts and

interrogated them for the following information. We found that

like GM, Ford also made a number of trannies capable of

fulfilling the needs of the weekend warrior, class racer, heavy

hauler, and Sunday driver. Follow along as we take an in-depth

look at the two-speeds, three-speeds, and the overdrive units. |

|

Two Speeds |

|

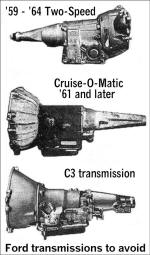

Ford offered a "Fordomatic" two-speed between 1959 and 1964 in

six-cylinder applications exclusively (mainly in Falcons,

Comets, and so on). They are easily identified by their

one-piece aluminum case. Unlike GM's Powerglide, they offer no

performance advantages, so forget 'em. |

|

Three Speeds |

|

Ford's various three-speed automatic transmissions came in a

number of applications and a variety of types. The lightest duty

of the three-speed automatic transmissions, the C3, and the

oddball "Cruise-O-Matic" series probably won't be of any

interest to many car crafters. From a V-8 performance

standpoint, there are really only two transmissions to consider

- the C4 and the C6.

The C4

Introduced in 1964, the C4 was Ford's first light-duty

three-speed automatic transmission. It was used behind

four-cylinders, six-cylinders and small V-8s by all Ford

divisions (Ford, Lincoln and Mercury). An interesting feature of

the C4 is its bolt-on bellhousing, which allows it to be easily

adapted to a variety of engine applications. There are two major

C4 case variations with respect to dipstick location: Those with

the dipstick in the case were primarily used in passenger cars,

while those with the dipstick entering directly into the trans

pan were used mainly in trucks, vans and some fullsize cars. On

transmissions with the dipstick in the pan, the bolt-on

bellhousing was also make larger to accommodate a 12-inch torque

converter (the smaller-cased units housed an 11-inch torque

converter). Internally, both versions of the C4 are the same. A

lockup version called the C5 was introduced in 1982 and

continued in use until production ended in 1986. The C5 used a

lockup converter and different valvebody programming, but it was

otherwise similar to other C4 transmissions. C4s were original

equipment behind 260, 289, 302, and 351W V-8s.

Harvey Baker of Performance Automatic Transmissions, makers of

some of the toughest C4s available, says the company prefers the

C4 over other Ford offerings because they are light and

efficient, ranking along with the GM Powerglide and the Chrysler

904 as the least-power-robbing automatics. If there is a weak

point, Baker says, the stock planetary is the component most apt

to fail on a C4. To address this, Performance Automatic builds a

rollerized planetary system (see Fig. 4), which is used in it's

"Super Comp" series of race-ready C4s rated for engines

producing up to 1,200 hp and 800 lb-ft of torque. Super Comp

transmissions feature standard gear spacing (see chart below), a

hardened 26-spline input shaft, the rollerized planetary system,

six-gear pinion, six-clutch drum, and a lifetime warranty.

Performance Automatic claims to have yet to experience breakage

with one of its Super Comp C4s, and the company is so confident

in its strength that it recommends this unit over even a

beefed-up C6.

|

Fig. 01 - Fords automatic transmission

offerings

Fig. 02 - 3-spd ID

Fig. 03 - The Ford transmissions to avoid

Fig. 04 - Rollerized C4 planetary system from

Performance Automatic Transmissions. |

|

The C6

The C6 is to the C4 what the GM Turbo 400 is to the Turbo 350.

Introduced in 1966 and produced until 1989, the heavy-duty C6

was used behind engines ranging from the 351W to the 7.3 Diesel.

Before the advent of race-prepped C4s, the C6 was the auto trans

of choice in performance/race applications. One-piece-case C6s

came in three different bellhousing patterns to accommodate the

three different series engines offered by Ford:

-

small-block

(260, 289, 302, 351W, and 351C)

-

FE-series

big-block (332 to 428)

-

335-series

(429 and 460, plus the 351M and 400, which shared the same

bellhousing pattern

|

|

Three different extension housings (tailshafts) were offered:

the Lincoln version at 17.4 inches long; the truck housing at 7

inches long; and, most commonly, the 14-inch length used in

passenger-car applications.

According to Pro-Formance's Sean Wiley, the C6 really has no

basic weaknesses, and it can withstand obscene amounts of power

in stock form. A good intermediate lever and servo, and a

later-model four-clutch drum modified to accept five clutches

are pretty much all that's needed to fortify the already beefy

C6. Nevertheless, Wiley only recommends their use behind very

powerful big-blocks where the power required to drive the

transmission is less significant. Mike Stewart of Mike's

Transmissions considers the C6 to be ideal for tow vehicles

where the owner isn't concerned with squeezing out precious

tenths of a second, as the internals are so heavy that they eat

inordinate amounts of power.

ATI's Chris Esterly concurs with Stewart, informing us that ATI

rarely builds C6s for performance applications but does so

occasionally for tow vehicles or restorations of musclecars

originally equipped with the C6. With today's crop of small,

high-horsepower motors, the heavy rotating mass of of the C6

simply kills power. Packaging is also difficult, as the massive

C6 doesn't fit easily into many cars.

|

Fig. 05 - Here are the three V-8 bolt

patterns offered on Ford automatic transmissions. |

|

The

Cruise-O-Matic

Introduced in 1951, the Cruise-O-Matic series of three-speed

automatics (which includes the FMX) was used in Ford, Lincoln

and Mercury passenger cars until 1979, and in light trucks from

1968 through 1979. They came in three configurations:

-

the small

case (from 1951 to 1966)

-

the medium

case (from 1955 to 1968), and

-

the FMX

(from 1967 to 1979)

The Cruise-O-Matic transmissions are easily identified by their

design, which incorporates a cast-iron main case (unlike all

other Ford three-speed automatic offerings) with separate

aluminum bellhousings and extension housings bolted to it. The

Cruise-O-Matics should be avoided in performance applications as

very little is available in the way of aftermarket performance

parts other than shift kits. The Cruise-O-Matics were also

offered with all three bolt-common V8-pattern bellhousings.

|

|

|

The AOD |

|

Ford's automatic overdrive (AOD) for rear-wheel-drive

applications was the first of it's kind offered by an American

automaker back in 1980. Featuring mechanical lockup, it was

available behind everything from the 3.8L V-6 through Ford's

Windsor-style V-8s (the 5.0L and 5.8L). The later automatic

overdrive electric (AODE) incorporated computer control.

|

Fig. 05 - 4-spd automatic overdrive ID |

|

According to Mike Stewart of Mike's Transmissions, one of the

most common problems with the AOD is its tendency to burn up the

overdrive band. Mike's Transmissions offers a variety of parts

to bolster the capabilities of the AOD, including an "A+" servo

with grater capacity than stock and a hardened 4340 chromoly

input shaft to replace the notoriously weak lockup input shaft.

Mike's Transmissions also retrofits the larger and stronger

drum/band assembly from the newer AODE to non-electric

AODs. Stewart considers a well-prepped AOD to be capable of

withstanding 700 to 800 hp comfortably, making it safe for use

in street applications less aggressive than all-out race cars. |

|

Canada's Lentech Automatics has a reputation for building the

world's toughest AODs. When asked about the weakest link

in the AOD, Lentech's Chris Nugteren quickly points to an

inherent problem with the power flow through the transmission.

The AOD incorporates a somewhat rudimentary overdrive design

featuring two input shafts. The inner shaft, which is driven

directly from the front cover of the torque converter bolted to

the flywheel, provides direct drive in Third gear and bypasses

the hydraulically driven components of the torque converter

entirely; the hollow outer shaft is driven hydraulically by the

converter and drives First, Second, and Reverse gears. This is

commonly referred to as a split torque path, and it allows 40

percent of the engine's torque to be transmitted via fluid

coupling (through the torque converter) and 60 percent to be

transmitted mechanically while the transmission is in Third

gear. In Fourth gear, 100 percent of the torque is transmitted

mechanically - similar to the direct-drive of a

manual trans.

When building an AOD transmission for a mild street/strip

applications, Lentech first substitutes a nonlockup-style torque

converter, which allows hydraulic damping to reduce the shock

transmitted to the inner shaft compared to a lockup converter.

Another benefit of the nonlockup converter is that Third gear

now receives torque multiplications from the converter rather

than being driven directly by the crankshaft as with a manual

transmission. The result is more potential speed and smoother

operation without the lockup feature. Lentech offers hardened

inner and outer input shafts in the standard spline count.

Another major component of the AOD that needs to be addressed in

a performance applications is the valvebody, which, in

Nugteren's words, "has a shift pattern that sucks." The AOD was

introduced at a time when Ford's automatic-equipped cars rolled

off the assembly line with only three-position column detents.

Rather than design a new column, Ford (during it's "Better

Ideas" days) opted to provide only three shift positions for the

new transmission: First, Drive, and Overdrive, bypassing Second

gear entirely in a manual-shift situation. Mustang owners

quickly learned that if they upshifted from First to Third

(Drive), then quickly downshifted back to First before the trans

made the shift into Third, the trans would hold Second gear

until the driver manually upshifted to Third.

While this technique will work for a while, the overdrive band

and direct clutch will prematurely wear out. Lentech changes the

shift pattern by making a specific gate for Second gear and

combining Overdrive with Drive. Overdrive is controlled with an

electric solenoid in the valvebody (like most overdrive

transmissions).

|

|

Lentech covers mild, but what about wild? The company starts by

replacing the two-piece input shaft with a one-piece nonlockup

4340 chromoly unit (see photo) offered in two states. Stage One

shafts feature a standard spline count, while State Two

one-piece input shafts are offered in larger diameters and

feature higher spline counts. They also offer a matching direct

drum and torque converter. |

Fig. 04 - Ford's AOD comes equipped with a

two-piece input shaft (left) but Lentech Automatics

offers a one-piece 4340 chromoly replacement to

handle brutal horsepower. |

|

Next, the valvebody is replaced with a Lentech unit that applies

two clutch packs to Third gear. Normally only the direct-drive

clutch pack would be used, but the reverse clutch pack is added

to the function, spreading the load over two sets of splines and

friction elements (drums), and allowing it to hold huge

horsepower. It's this single development that has made Lentech's

ultimate AOD transmissions virtually bulletproof. They further

modify the transmission by removing the Fourth (Overdrive)

gear and replacing many of the components with lightweight

pieces. In applications where a "loose" or high-stall converter

is used, Lentech maintains the lockup function of the converter,

enabling it to eliminate the slippage that plagues high-stall

converters. On of its race units is in a Mustang running 8.20s

at 165 mph with no breakage in a full season's use. We would say

that it works!

The AODE is essentially an electronically controlled AOD

transmission, sharing most of its internal parts except for the

input shaft, which has its lockup function controlled

electronically by a computer. As mentioned above, the drum/band

assembly is slightly larger and made of stamped steel (unlike

the cast-iron drum used in the standard AOD), and it is

interchangeable with its counterpart. One advantage enjoyed by

the AODE is that the shift functions and characteristics of the

transmission can be programmed for greater versatility, but this

creates its own unique set of problems.

Ford programmed the AODE to provide seamless transitions between

gears, accomplishing this with a pressure-control solenoid (PCS)

that manipulates the line pressure in the transmission to soften

shifts. Ford also attained seamless shifting by slipping the

converter clutch, which cycles the converter in and out of

lockup. Unfortunately, this prematurely wears out the clutch

materials, which can send debris through the system. Lentech

insists that the first thing to do with an AODE is to add a

performance computer chip that corrects the pulse width of the

PCS and eliminates the multiple personality of the lockup

feature. |

|

|

Other Overdrives |

|

The 4R70W is a wide-ratio version of the AODE featuring a 2.84:1

First-gear-ratio. The E4OD (later renamed 4R100) is still used

in extreme-duty truck applications. It's basically a C6 with an

add-on overdrive unit, making it so massive it's really not

suited for anything other than a truck chassis. But before you

dismiss the E4OD trans as being for tow rigs only, consider it's

the trans used on Ford's Lightning trucks. While not the most

efficient trans, it's capable of absorbing an inordinate amount

of abuse, and its warranty is second to none in the Ford Motor

Company transmission lineup. Lentech also modifies these for tow

and race duty in a similar manner to the AOD. Early E4ODs are

retrofitted with the later 4R100 steel overdrive planetary and

ball-bearing center support, extra clutches are added, the valvebodies are reprogrammed, and an aftermarket torque

converter is usually installed. Lentech is also in the process

of developing a transbrake for use in Lightning trucks in

racing.

Barely worth mentioning is the A4LD trans and the five-speed

derivatives, the 5R55N and 5R55W. These transmission were

introduced in 1985 and used exclusively behind four- and

six-cylinder engines. They are currently still in use by Ford,

based on the C3 three-speed automatic. |

Fig. - The E4OD is Ford's heaviest duty overdrive

automatic transmission. |

Ford Automatic Transmission Guide

This list is not conclusive or absolute, but provides

general guidelines with respect to power ratings. |

|

Trans |

Years |

Case Type |

Trans Usage * |

Vacuum

Modulator

Location |

Kickdown

Cable |

Small-

Block |

FE |

335 |

Stock |

Modified |

|

C3 |

'74-'87 |

- |

- |

- |

D |

D |

right center |

rod |

|

C4 |

'64-'86 |

X |

- |

- |

D |

B |

right rear |

rod |

|

C6 |

'66-'89 |

X |

X |

X |

A |

A |

right rear |

rod |

|

Cruise-O-Matic |

'51-'79 |

X |

X |

X |

C |

C |

right rear |

rod |

|

AOD/AODE |

'80-up |

X |

- |

- |

C |

B |

none |

rod or cable/electric |

|

E4OD/R4100 |

'89-up |

X |

- |

X |

A |

A |

none |

electric |

|

*

Ratings: A=High torque, heavy car; B=High torque, light car;

C=Low torque, heavy car; D=Low torque, light car |

|

Gear Ratios of Popular Ford Automatic Transmissions |

|

Trans |

1st |

2nd |

3rd |

4th |

|

C4 |

2.46 |

1.46 |

1.00 |

- |

|

C5 |

2.46 |

1.46 |

1.00 |

- |

|

C6 |

2.46 |

1.46 |

1.00 |

- |

|

AOD |

2.40 |

1.47 |

1.00 |

0.67 |

|

AODE |

2.40 |

1.47 |

1.00 |

0.67 |

|

4R70W |

2.84 |

1.55 |

1.00 |

0.70 |

|

E4OD/4R100 |

2.71 |

1.54 |

1.00 |

0.71 |

|

SOURCES |

-

ATI

PERFORMANCE PRODUCTS - 6747 Whitestone Rd.,

Baltimore, MD 21207 -

800.284.3433

-

DYNAMIC

CONVERTERS / PRO-FORMANCE TRANSMISSION - 122 Sandy Dr., Ste F,

Newark, DE 19713

-

LENTECH

AUTOMATICS - 3487 Joy's Rd.,

Richmond, ON, Canada K0A 2Z0 -

613.838.5390

-

MIKE'S

TRANSMISSION - 42541 N. 6th St. E., Unit 11,

Lancaster, CA 93535 -

661.723.0081

-

PERFORMANCE

AUTOMATIC INC. - 8174 Beechcraft Ave.,

Gaithersburg, MD 20879 -

800.767.8174 -

301.963.8078

|

|

|

|

Want to link to

this site? Please save this banner to your hard drive to place on your

webpage.

The correct link to use is

http://www.fordification.com

|