|

|

|

|

|

Some of the more

commonly-asked discussions on the Ford truck forums and

groups revolves around the brake setups...specifically,

proportioning valves...as well as several other

brake-related components that are consistently misidentified

as proportioning valves. Knowing what each of these

different components actually are and how they function is

the key to understanding how your truck's brake system works

and how to properly troubleshoot it when problems arise, so

let's discuss these in detail...

First of all, let's

start out with a few facts:

1) All Ford F100s up through 1972 only

had drum brakes front and rear. However, disc brakes

were an available option on F250/350 starting in 1968.

They became standard equipment on F100s in '73.

2) Vehicles with 4-wheel drum brakes don't need a proportioning

valve, while vehicles with disc brakes and rear drums DO need a proportioning

valve! (More on this later.)

3) Ford did not start installing a disc-brake

proportioning valve in their trucks until 1973. Even the

'68-'72 F250/350

with front disc brakes didn't have a proportioning

valve. Their brake 'add-ons' include only a brake

pressure differential valve and a stand-alone metering valve.

|

|

Starting in 1968,

Dayton dual-piston caliper disc brakes were an available

option on F250/350 models only (shown at right). This was a new

technology for Ford and they were still trying to fine-tune

them and match them to the completely-different operating

characteristics of the rear drum brakes.

Therefore, the

brake proportioning valve as we know it today hadn't even

come onto the Ford truck scene yet. The brake line circuits

only contained two 'add-on' components: the brake

pressure differential valve and a

stand-alone metering valve. Both of these

two components are often improperly

misidentified as a proportioning valve....and

that misidentification tends to cause a lot of

problems. |

CLICK TO ENLARGE |

|

So let's examine

these two components and discuss what they

actually are. |

|

| Brake Pressure

Differential Valve |

| |

|

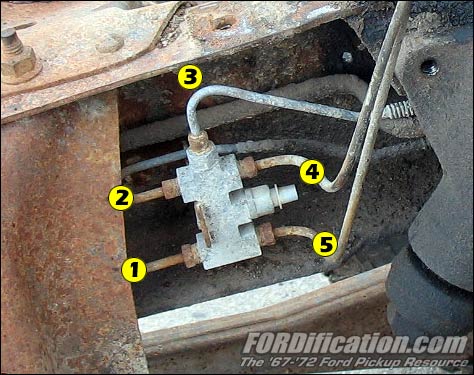

The little device mounted

inside the left framerail, just below the driver's seat area, is

a BRAKE PRESSURE DIFFERENTIAL VALVE. It is NOT

a proportioning valve, nor is it a 'distribution block'! It's important to understand

this...and what's it's actual function is. It has no

proportioning features to it whatsoever and doesn't affect

brake performance in any way. The stand-alone brake pressure

differential valve is used on all '67-'72 trucks, 2WD and

4WD, regardless of whether the truck is equipped with front

disc or front drum brakes. The little device mounted

inside the left framerail, just below the driver's seat area, is

a BRAKE PRESSURE DIFFERENTIAL VALVE. It is NOT

a proportioning valve, nor is it a 'distribution block'! It's important to understand

this...and what's it's actual function is. It has no

proportioning features to it whatsoever and doesn't affect

brake performance in any way. The stand-alone brake pressure

differential valve is used on all '67-'72 trucks, 2WD and

4WD, regardless of whether the truck is equipped with front

disc or front drum brakes.

1 - Rear

2 - Left-front

3 - Right-front

4 & 5 - Master cylinder |

|

CLICK TO ENLARGE

This diagram from the Ford

Truck Shop Manual isn't 100% accurate, as the factory piece

actually used has 5 ports (plus the switch port) as opposed

to the 4-port Mustang version showed here. However, the

principle is the same. |

Unlike a metering valve or

a proportioning valve, a pressure differential valve doesn't

have any preset pressure settings to delay or to reduce the

hydraulic pressure being applied. It's just a spool

suspended and balanced inside the valve body between equal

pressures of the front and rear brake circuits. If the pressure in either circuit is unequal, the spool is pushed

to the low pressure side, closing the switch contacts and

illuminating the dash-mounted warning light...simple. It

doesn't have any metering function for the front brake

circuit and no proportioning function to the rear brake

circuit like the all-in-one brake assemblies (see

'Combination Valve' below) installed during the '73-'79

trucks.

|

CLICK TO ENLARGE |

|

Once

the problem that caused the warning light to illuminate has been corrected, the piston must be

re-centered to turn off the warning light.

The warning light mounted

on the lower-left of the dash, just above the parking brake

assembly, is often mistakenly associated with the parking brake,

due to it's proximity. However, as mentioned above,

the dash-mounted brake warning light is only hooked up to

the brake pressure differential valve and is NOT connected

to or associated with the parking brake in any way! The warning light mounted

on the lower-left of the dash, just above the parking brake

assembly, is often mistakenly associated with the parking brake,

due to it's proximity. However, as mentioned above,

the dash-mounted brake warning light is only hooked up to

the brake pressure differential valve and is NOT connected

to or associated with the parking brake in any way! On '68-'72 models, if the

system is working properly as designed, the warning light

will come on when the ignition switch is in the "START"

position as a way to prove that the bulb and circuitry is

functioning correctly. It shouldn't come on in any other key

position. However, '67 has only one wire on the pressure

differential switch and doesn't have the Prove Out circuit

of the 2nd wire to make the warning light momentarily flash

in the start/crank ignition switch position. The '67

pressure differential switch takes a 1/2" wrench/socket to

remove/install. The '68-'72 pressure differential warning

switch will require a 9/16" wrench socket to remove install,

but the threads at the base of both switches are 3/8"-24, so

they can be physically interchanged at the valve body. |

|

The owner's manual

gives a brief description of the warning light and it's

function. Some truck owners misinterpret the 'brake warning

light' label as meaning parking brake, but it's actually for

the hydraulic portion of brakes. From the 1969 owner's

manual:

|

|

One myth that often pops up during

conversations is the misconception that if the spool in the

pressure differential valve gets pushed off-center due to

(for example) a brake line failure, it seals off the bad

side, allowing you to still have brake pressure on the good

side. This is incorrect! It is merely a warning

system. The ends of the spool are turned down to allow brake

fluid to pass when it is pushed to one side. If the spool

was designed to cut off the brake fluid to the side where

the pressure has dropped it would seal the fluid between the

master cylinder and the distribution block. This would cause

the brake pedal to be rock hard and you would have no brakes

at all because the trapped fluid would not give. The dual

master cylinder is the safety feature that allows pressure

at the good end. There is nothing inside the pressure

differential valve to replace when rebuilding except for two

special o-rings and a crush washer. |

|

Pressure Differential Valve Part Numbers |

|

1967-1972 |

| 67 |

F100 4x4 |

C7TZ-2B257-B |

| 68/ |

F100 4x4 |

C8TZ-2B257-B |

| 67 |

F100/250 4x2, F350 |

C7TZ-2B257-E |

| 68/ |

F100/250 4x2, F350 |

C8TZ-2B257-D |

| 67 |

F250 4x4 |

C7TZ-2B257-D |

| 68/ |

F250 4x4 |

C8TZ-2B257-C |

| 68/ |

F250/350 |

C8TZ-2B257-G |

|

Reseal kits are available

for some pressure differential valves through

www.MuscleCarResearch.com. These utilize the special

square O-rings necessary to withstand the corrosive nature

of brake fluid. Do not use Buna-N (Nitrile) o-rings in the

brake system as it is not a compatible material. Butyl or

EPDM are the only commonly available materials you should

use. Others include Virgin Teflon, Styrene Butadiene and

Aflas.

A rebuilding tutorial on

PDF is

also available

HERE.

NOTE: The only difference

between the drum/drum pressure differential valve used on

cars vs. trucks is their mounting brackets. The valve body

and internals/seals themselves are the same. |

|

|

|

There

were several different types of pressure differential valves

used on the dentside-era ('73-'79) 2WD trucks. Primarily

though, there were two that were most commonly used. These

two are pictured here with the typical bumpside-era piece

(left). Usually the cast iron Kelsey-Hayes brake valve

(middle) was used in trucks 6,800 lbs or under and the brass

Weatherhead valve (right) was used in trucks over 6,800 lbs. There

were several different types of pressure differential valves

used on the dentside-era ('73-'79) 2WD trucks. Primarily

though, there were two that were most commonly used. These

two are pictured here with the typical bumpside-era piece

(left). Usually the cast iron Kelsey-Hayes brake valve

(middle) was used in trucks 6,800 lbs or under and the brass

Weatherhead valve (right) was used in trucks over 6,800 lbs.

|

|

|

C8AZ-2B264-A - Brake

Pressure Differential Valve Warning Lamp Switch

Available from Ford and auto parts stores

1968/69 FoMoCo passenger cars

1968/79 F100/350, Bronco & Econoline

Some 1970/79 FoMoCo passenger cars |

|

|

|

|

This is a Pressure Differential Switch Lock

Tool available from

MuscleCarResearch.com or

National Parts Depot. To use it, you first remove the

pressure differential switch from the main valve body and

install this in its' place, to hold the spool in a centered

position while the brakes are being serviced and/or bled. If

you remove the electrical switch and brake fluid seeps out,

the O-rings in your unit have failed and must be replaced.

Once the servicing is completed, you can remove this tool

and replace it with the electrical switch. |

|

| Metering

Valve |

|

The stand-alone disc brake

metering valve

(a.k.a. "hold-off" valve) was only used

on '68-'72 F250/350 2WD trucks with the optional dual-piston

caliper front disc brakes. It's located on the left/rear

area of the main front frame crossmember and plumbed inline

into the front brake circuit between the brake pressure

differential valve and the front disc brake calipers.

The metering valve is just

a hydraulic pressure delay device. It gives the rear brake

circuit a little bit of a head start for the wheel cylinders

to fill with fluid, overcome the tension of the brake shoe

retracting springs and begin moving the shoes toward contact

with the drums, before the front discs begin to apply.

I don't know the specific pressure rating of these

particular metering valves but it's generally around 100 PSI

(give or take). Before this point, the metering poppet valve

is held closed by a coil spring, of a given wire diameter.

Once the pressure in the brake lines builds to a sufficient

level to overcome the tension and compress the poppet

against the spring, the poppet is forced open and brake

fluid and pressure are allowed to reach the brake calipers

thus, applying the front brakes in conjunction with the

rears. |

|

And once again, it needs to

be stressed that this is NOT a proportioning valve!

|

C8TZ-2B161-A .. Brake Pressure Metering Valve -

Use with disc brakes (Obsolete)

1968-72 F250 2WD & F350

1973-78 F350

1973-79 F250 2WD w/single or dual piston caliper front disc

brakes

1979 F350 2WD

|

| Combination Valve |

|

|

|

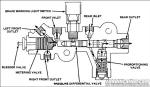

Left:

This is the combination valve as used on

'73-later trucks equipped with front drum and rear disc

brakes for trucks under 6,800# GVW. |

|

|

In

1973, Ford integrated the pressure differential valve and

the metering valve into a single valve body assembly on the

disc/drum trucks. And for the first time in the trucks, a third

function (proportioning) was also added to this integrated

brake valve assembly, so it now had 3 separate brake functions:

1) a metering valve (for the

front disc brakes)

2) a proportioning valve (for the rear drum

brakes)

3) the familiar brake pressure differential

valve (sensing in between the primary and secondary brake

circuits)

People often mistakenly

refer to this complete assembly as the proportioning valve...and

while that's

not entirely inaccurate, it's actually called a 'combo

valve' because it includes three different components with

completely different functions integrated into a single unit...it's

more than just a proportioning valve.

Contrary to popular belief, the

proportioning valve does not limit the pressure to the rear

brakes. It reduces the rate of pressure rise to the rear

brakes in proportion to the pressure being applied to the

front brakes

during a hard stop.

Regardless of what type of brakes a car has, the rear brakes

require less force than the front brakes. The amount of brake force

that can be applied to a wheel without locking it depends on

the amount of weight on the wheel. More weight means more

brake force can be applied. If you have ever slammed on your

brakes, you know that an abrupt stop makes your car lean

forward. The front gets lower and the back gets higher. This

is because a lot of weight is transferred to the front of

the car when you stop. Also, most cars have more weight over

the front wheels to start with because that is where the

engine is located.

If equal braking force

were applied at all four wheels during a stop, the rear

wheels would lock up before the front wheels. The

proportioning valve only lets a certain portion of the

pressure through to the rear wheels so that the front wheels

apply more braking force. If the proportioning valve were

set to 70 percent and the brake pressure were 1,000 pounds

per square inch (psi) for the front brakes, the rear brakes

would get 700 psi.

So how does it work? Well, under normal braking use, the

poppet of the proportioning valve sits dormant and does

nothing. This means under normal braking, the pressure being

applied to the front brakes is also the same pressure being

applied to the rears.

In the

event of a panic stop, the brakes' hydraulic

system experiences a sudden spike/rise in line pressures and there's a

sudden shift in vehicle weight from the rear to the front. The nose

dives and places more downward force on the front tires. The upward lift

of the rear unloads the weight over the rear tires.

This reduction in rear weight makes it very susceptible for the rear

drums to lock up. The abnormally-higher line pressures to the rear

causes the fluid to push on the poppet of the proportioning valve. This

overcomes the tension of the coil spring of the poppet valve and pushes

the valve over the fluid passage to create a partial blockage. This

reduces the opening of the valve body fluid passage and reduces the rate

of pressure rise being applied to the rear drums.

Factory proportioning circuits are engineered for the vehicle it's

installed on. Different vehicle GVWs will dictate the spring rating on

the proportioning poppet valve and when it will begin to

operate (knee-point of the pressure curve in proportion to

the pressure being applied to the front brakes).

Not all OEM proportioning valves come with

the same spring/pressure rating so they will not all become

active at the same pressure application point in the brake

system. So that's the reason Ford listed the proportioning

valves for the light 6200# GVW 4x2 F250 dentside pickups

with the F100/150s...and the heavier 6900#, 7500# and 8100#

GVW 4x2 F250s with the 4x2 F350s.

|

|

CLICK TO ENLARGE |

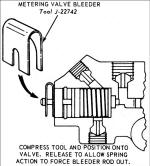

If you look at the front

end of the combo valve, there's a brass pin just in front of

a rubber boot. This is the metering valve bleeder and is

something you don't want to forget about when attempting to

bleed your front disc brakes. A special tool pulls

outward on the pin to allow the brake fluid to reach the

caliper assemblies. This operation is particularly important

if pressure bleeding is being used.

In a pinch, you

can use a small pair of ViseGrips to hold the pin out for

bleeding purposes, but it's recommended to either find the proper

tool or build yourself one from a piece of sheetmetal. |

CLICK TO ENLARGE |

|

|

| By Keith Dickson

(FORDification) and Steve Ainsworth (ultraranger) |

|

|

|

Want to link to

this site? Please save this banner to your hard drive to place on your

webpage.

The correct link to use is

http://www.fordification.com

|