|

The

Borg Warner Overdrive Transmission began its life in the

1930s and was last used anywhere in the automotive industry

in Ford trucks in 1972. Overdrive was last used in Ford passenger

cars in 1967.

This

article is to explain this unique transmission and its

features to Ford truck owners & enthusiasts in the hopes

that they will have a better understanding of how fortunate

they are to have acquired one and better understand how to

operate, repair, and enjoy it.

Popularity of the B-W OD lessened over its long production

life, especially after availability of fully automatic

transmissions, but it still remains the most versatile

transmission ever put into a vehicle. However, to maximize

its full operating potential, the driver must understand

what it does and how it works. Unfortunately the chances of

a 21st-century truck buyer who might be lucky enough to come

across an overdrive-equipped Ford truck appreciating how

lucky a find they have diminishes every year. It then

becomes ever more likely that the marvelous overdrive set up

would be removed and the truck converted to another

transmission type...a sad loss indeed.

There

are many ways to “overdrive” a vehicle. To overdrive

something is to gear it in such a manner that more

revolutions come out of a gear set (the transmission) than

went into it. Overdriving a running gear (motor,

transmission & axle combination) lowers the revolutions that

the engine spins at any set speed, but overdriving also

exchanges this lower engine speed for less of a mechanical

advantage - less able to pull away from a stop, the less

able to pull a load, the less able to pull a hill. In the

simplest terms, overdrive acts like a super-high gear that

is intended to be used only at freeway speeds to lower the

engine revolutions, lower engine wear and lower both engine

oil and fuel consumption.

Overdriving a vehicle can be done in many ways, such as

adding an additional entire transmission (like a Brownie

auxiliary transmission) or adding an additional ‘gear’ to

the existing transmission (like modern five-speed

transmissions, where 5th gear is overdrive). An overdrive

ratio can also be created with a planetary gear set. (This

is how a Borg-Warner OD transmission accomplishes an

overdrive ratio).

A

planetary gear set is what exists in most automatic

transmissions. You can read elsewhere about how the holding

and releasing of the sun, planet and ring gears give various

ratios, but for the purpose of understanding how a B-W OD

system works all that needs to be remembered is that when

the sun gear is held and the planets are driven by the

transmission the output shaft, then more revolutions are

sent to the driveshaft than went into the transmission.

Holding and releasing the sun gear is all it takes to make a

B-W OD transmission go into and out of overdrive. A

planetary gear set is what exists in most automatic

transmissions. You can read elsewhere about how the holding

and releasing of the sun, planet and ring gears give various

ratios, but for the purpose of understanding how a B-W OD

system works all that needs to be remembered is that when

the sun gear is held and the planets are driven by the

transmission the output shaft, then more revolutions are

sent to the driveshaft than went into the transmission.

Holding and releasing the sun gear is all it takes to make a

B-W OD transmission go into and out of overdrive.

History and operation of the

Borg-Warner Overdrive Transmission

The B-W

OD transmission originated during the 1930s to solve a

number of problems that existed on cars at that time. It

uses a freewheeling clutch that began life in the 1920s and

later added a planetary gear set (operated as a purely

mechanical device in the early 30s) and eventually finalized

the design by using electrical components to operate the

system by the late 1930s. Most every automotive manufacture

offered the B-W OD set up as an option on their cars at one

time during their production life.

Manufacturers who focused their marketing toward operating

economy were all heavy promoters of the B-W overdrive.

Studebaker probably made more OD-equipped vehicles than

anybody. Other AMC marques (Hudson, Rambler, Nash) were also

big users. Ford first offered the Borg-Warner OD on Lincoln

Zephyrs beginning in 1941. Fords and Mercurys received the

B-W OD as an option in 1949 and the F-series trucks got OD

for 1953. (Before 1941 & 1949 Ford, Lincoln & Mercury used a

two speed axle to lower engine revolutions – The Columbia

axle - not discussed here).

To

understand the B-W OD, the features it has and how to

properly drive it, one needs to understand the driving

conditions that existed during the 1930s & 40s. At that time

all vehicles were operated by a low horsepower (80-100HP)

low compression engine, with a very long stroke (4+ inches

would not be unusual). This engine design is very

appropriate for in town driving conditions. (start & stop,

no hills and speeds that do not exceed 40 mph).

To make

it possible for a low power 1930s-40s engine to climb hills

and haul loads manufactures installed very low rear axle

ratios. (High numerically) 4:10+ was common and some

vehicles approached and sometimes exceeded a 5:1 ratio.

These ratios made it possible to climb a hill (road building

technology was equally behind 21st century techniques,

grades were steeper back then) but would also spin an engine

very fast at highway speeds. (60 mph was exceptionally fast

in 1940!) Overdrive transmissions made modern freeway speeds

possible while saving gas, oil and engines. (Thrown rods

were common in the 1930s & 40s).

A

Borg-Warner OD has sometimes been called a ‘cable-operated’

overdrive...IT IS NOT! A B-W OD is electrically operated.

The only control visible to the driver is a cable located

somewhere on the dashboard. However all this cable does is

‘lock out’ the entire system. When the knob/cable is pulled

out the transmission operates entirely as a standard

three-speed transmission. With a properly-operating system

and knowledgeable driver, the cable will be pushed in 90% of

the time. When the OD cable IS pushed in, the first

operating feature of the B-W OD transmission becomes

apparent it “freewheels”. This means that while the engine

can drive the wheels, when the vehicle coasts, no power is

fed back to the engine. No engine braking, just coasting. A

Borg-Warner OD has sometimes been called a ‘cable-operated’

overdrive...IT IS NOT! A B-W OD is electrically operated.

The only control visible to the driver is a cable located

somewhere on the dashboard. However all this cable does is

‘lock out’ the entire system. When the knob/cable is pulled

out the transmission operates entirely as a standard

three-speed transmission. With a properly-operating system

and knowledgeable driver, the cable will be pushed in 90% of

the time. When the OD cable IS pushed in, the first

operating feature of the B-W OD transmission becomes

apparent it “freewheels”. This means that while the engine

can drive the wheels, when the vehicle coasts, no power is

fed back to the engine. No engine braking, just coasting.

When

the electrical components of a B-W OD are not functioning

this is all that the transmission will do - freewheel.

Freewheeling at speed is dangerous and can lead to loss of

control due to increased brake use. However a properly

functioning B-W OD does NOT freewheel at speeds above 28

mph. In a properly functioning OD engine braking DOES

happen. The thought that engine braking is not possible is a

major misconception for a B-W OD transmission.

The

other operating control for a B-W OD transmission is not

readily visible to the driver (and not visible at all from

the driver’s seat of a 67-72 Ford truck) it is the kick down

switch. The kick down switch is a push button type switch

that is operated only when the accelerator is fully

depressed (mashed to the floor) Before 1967, Ford trucks

used a switch design that goes all the way back to the

1930s. It protruded through a hole in the floor and was

activated by the back of the gas pedal. Starting in 1967

(1963 for cars) the kick down switch migrated to the

firewall and was operated by the throttle linkage. The

other operating control for a B-W OD transmission is not

readily visible to the driver (and not visible at all from

the driver’s seat of a 67-72 Ford truck) it is the kick down

switch. The kick down switch is a push button type switch

that is operated only when the accelerator is fully

depressed (mashed to the floor) Before 1967, Ford trucks

used a switch design that goes all the way back to the

1930s. It protruded through a hole in the floor and was

activated by the back of the gas pedal. Starting in 1967

(1963 for cars) the kick down switch migrated to the

firewall and was operated by the throttle linkage.

Driving with overdrive

Driving

a B-W OD vehicle starts off with the cable pushed in and the

truck pulling away in first gear as normal. The truck

accelerates and the driver shifts into second gear. At

approximately 28 mph (BTW - nobody knows why 28 mph and not

25 or 30 mph) a small click can sometimes be heard from

under the hood (activation of the relay on the firewall by

the governor on the transmission) the driver then backs off

on the gas and the transmission automatically shifts into

overdrive. The shift feels exactly like a shift from an

automatic transmission.

The

driver must release the accelerator completely such that the

power comes back from the wheels toward the engine to

complete the shift to OD. In an automatic transmission a

shift will occur (eventually) even if the throttle is held

open. For mechanical design reasons in a B-W OD set up, the

driver MUST let off the throttle completely to allow the

shift to happen.

With

the vehicle in second gear overdrive, the overall ratio is

not quite as high as third, but higher than second. This is

a perfect ratio for in town use. Between stoplights you

don’t need to shift into third. However, if you continue

accelerating and shift into third (from 2nd OD) and you will

then be in third gear overdrive, the perfect ratio for the

highway.

An

often asked question is “Can you overdrive first gear?” The

answer is yes, however you would have to exceed 28 mph for

the system to activate. The real question then becomes ‘Can

you exceed 28 mph in first?’ 28 mph is pretty fast for first

gear so 1st gear OD is rarely achieved. This means that

while a B-W OD transmission has sometimes been called a ‘6

speed’ it is really provides only 5 practical forward

ratios.

While

you are in overdrive if you back off the gas you will feel

engine braking. (second or third) Because it is an overdrive

ratio, the braking is not as evident as if the transmission

were in 2nd or 3rd direct drive but the transmission does

NOT coast. If the transmission does coast, the OD set up is

not operating properly.

Third

gear OD is great for gliding along at highway speeds but it

can lack power for passing or hill climbing. To get the

transmission out of overdrive, mash the gas pedal to the

floor. The engine will rev up and when the pedal compresses

the kick down switch, it will suddenly and quickly shift

back into direct drive. This shift feels exactly like the

kick down of an automatic transmission. Complete your pass

or top the hill in direct gear, then let off the gas

completely for a moment and the transmission will shift back

into overdrive.

If you

begin slowing down and shift from third OD to second OD,

then slow down further as if approaching a stop light, as

soon as the speed falls below 28 mph the power to the OD

will be cut and the transmission will then be back in direct

drive.

This

automatic loss of OD is a designed in safety feature because

you must start out from a complete stop only in direct

drive. To try to start out from a standing start in

overdrive would create an incredible strain on the driveline

is certain to damage something or at least result in

increased clutch wear.

Owners

have sometimes rewired their systems and by-passed the

governor by adding a manual switch to turn the system on &

off. If this has been done it is very easy to forget and

attempt to take off from a stop in first gear-overdrive.

Doing this is as fool hardy as by-passing the neutral safety

switch on an automatic transmission.

So as you slow down below 28 mph you are automatically put

back into second gear direct drive. HOWEVER, because the sun

gear is no longer being held (no OD ratio) the transmission

will freewheel. This event can be very surprising to someone

who is not familiar with the operation of an OD transmission

as suddenly there is NO engine braking! Since this occurs

only below 28 mph there should not be much need for engine

braking and using the foot brake to stop the truck should be

just fine.

But

this is also where another novel aspect driving with a B-W

OD transmission becomes apparent. All B-W OD transmission

set ups (from all manufactures in all years) used a

non-synchronized first gear. They never built a B-W OD

transmission with a synchronized first gear.

By the

1960s full syncro transmissions were fully available, so why

didn’t they make a fully synchronized OD? Turns out a B-W OD

trans doesn’t need to be synchronized!

Drive

in second gear OD, slow down below 28 mph and the trans

falls out of OD and into freewheel mode. Step on the clutch

and pull the lever into first and you will find it slips

into first gear as easily as if it were synchronized! Even

if you are rolling.

This

‘synchro effect’ happens because the freewheeling clutch

prevents power from being transmitted from the driveshaft

into the transmission. Push in the clutch and there are NO

forces on the gears. When you pull the lever into first gear

it slips in easily. The most clashing you get when shifting

into first gear at a rolling speed, is a slight “ratcheting”

of the gear teeth that you would expect if you were shifting

from neutral into the low granny gear of a truck 4 speed or

the reverse gear in any transmission.

The

freewheeling feature also makes clutchless shifting

possible. Start in first, pull away and then WITHOUT

depressing the clutch pedal, back off the gas and shift into

second as easily as if you had pushed the clutch! If you

shift into third gear before 28 mph (and engaging the OD)

again there is no need to depress the clutch pedal to make

the shift. If however you have allowed the transmission to

engage the OD in second (backing of the gas) then depressing

the clutch is necessary to shift from 2nd to 3rd.

These

operational features are what made the B-W OD transmission

very desirable in the days before fully automatic

transmissions. (Especially with the ladies). No clashing

shifts into first; No clutch necessary to shift into second;

Automatic shift into second OD around town.

One

other aspect of the freewheeling clutch needs to be

discussed; parking and pushing.

Pulling

out the OD cable on the dash operates a lever on the side of

the transmission and mechanically locks the sun gear to the

planetary gears. (Ideally the cable should only be pulled

out while the vehicle is stopped).

When the OD cable is pushed in then the whole system just

freewheels. This happens as long as the vehicle is below 28

MPH (or the system has no electrical power) the OD will not

engage. This means that to push start an OD equipped truck,

the cable needs to be pulled out for the wheels to send

power to the engine when the clutch is released.

Parking

is the other situation that pulling out the OD cable is

necessary. If you park pointing downhill and put the shifter

into first, second or third without pulling out the cable,

the forward motion will freewheel over the engine and the

truck will roll away. There is no compression lock. To

overcome this you can either pull the OD cable out or place

the shifter into reverse.

In

order for any OD transmission to back up, the freewheeling

clutch MUST be locked out. There is a shaft/rod built into

the transmission that automatically accomplishes this

whenever the transmission is put into reverse. So to park

safely (set the brake) and then either pull out the OD cable

OR place the shifter into reverse. This locks up the

driveline and prevents all rolling.

Couple

the OD transmission with the very low rear end gears that

existed in the 30s & 40s and you effectively had an

automatic transmission. Owners manuals from that time

suggested that around town you could (should?) start out in

second gear slipping the clutch only slightly, (possible

with a very low rear end gearing) then letting the trans

shift itself into second overdrive. No need to touch the

lever and limited use of the clutch, what more could you ask

for?

Speaking of rear end gears how are they affected by the

overdrive? All B-W ODs overdrive function at a 0.7 overdrive

ratio. Since all transmissions use a 1:1 ratio in high gear,

to find out your final drive ratio in OD simply multiply the

rear end ratio by 0.7.

4.11 = 2.87 3.70 = 2.59

Even a very low 4.56 ratio can be tamed by an OD into a very

functional 3.19.

This is

what makes the B-W OD so appropriate for use in a truck. In

a truck a low geared rear end could help it haul a heavy

load but you don’t want to spin the engine so fast at

highway speeds or when the truck is empty. With a functional

OD you get the best of both worlds, strong low end pulling

AND practical highway and unloaded use.

An OD

can also compensate for small diameter wheels & tires.

Smaller wheels & tires spin an engine faster. 16” wheels

turn the driveline slower than 15” which spin the driveline

slower than 14” (as the wheels/tires get bigger they carry

more weight and lower the engine speed but they also reduce

the available power. All things are a compromise) All these

factors need to be considered when outfitting a vehicle with

a B-W OD transmission. If you use a rear axle ratio that is

too high (numerically low) and/or couple it with

wheels/tires that are too big in diameter a vehicle can

actually slow down or use more fuel when it is operating in

OD.

Troubleshooting Troubleshooting

The

Borg-Warner overdrive transmission combines both mechanical

and electrical components. The mechanical components are

very stout and as long as the transmission AND THE OVERDRIVE

unit is filled with gear oil (see maintenance below) the

only problems should be electrical, which are very easy to

trouble shoot.

Take an OD truck out for a test drive with the OD cable

pushed in, if it freewheels above 28 mph (and you don’t feel

the automatic shift) the trans is OK but there is an

electrical problem.

The OD

electrical system is protected by just one fuse clipped to

the relay on the firewall. This fuse gets power whenever the

key is turned on. Begin your diagnosis by checking for power

at both sides of this fuse. Because the relay is under the

hood, the fuse and its mounting gets very corroded, very

easily. Remove the fuse, and clean all the contacts

thoroughly. If there is no power here, trace the wire back

to the key switch to find the break.

Testing the system

If you

have good power on both sides of the fuse on the OD relay,

the next check is made under the vehicle. At the back of the

transmission is the governor. This is a cylinder shaped

device that is driven by the speedometer gear with ONE wire

coming out of it. Inside the governor are weights that spin

with the driveshaft. When they reach the magic speed of 28

mph, the wire going into the governor is grounded. The full

circuit is that simple!

For

some reason the insulation on wire at the governor is always

made from the same cloth used since the 1930s. This wire

always seems to have a frayed spot. With the ignition key

turned on, jump the wire to ground.

(There could also be a wire connector between the governor

and the OD harness. Pull it apart and ground the wire that

was going to the governor). However you ground the governor

wire, you should then hear a click from the relay on the

firewall.

Power

comes from the fuse through the relay, which is then

activated whenever it is grounded.

Power from the relay to the governor does pass through the

kick down switch. If there is no relay click when grounding

the governor, check for 12 volts at the wire and trace it

back to the kick down switch and then back to the relay to

find the open circuit.

If you

have 12 volts at the governor and you hear a relay click

when you ground the governor, then the relay should be

sending power down to the solenoid. (the steel can on the

side of the trans) As soon as the solenoid gets power, it

too should click. (the solenoid is trying to push its

plunger shaft into the trans) If the solenoid does not

click, check to see that it is receiving 12 volts of power

directly from the relay.

If you

have determined that 12 volt power is being sent to the

solenoid from the relay, the solenoid can be tested by

providing it with 12 volts directly. There are two wires on

the solenoid. One wire activates the plunger and if it is

given power, it should engage. The other wire goes directly

to ground (part of the kick down circuit). Clip your 12 volt

power source to one of the wires, it should either activate

the solenoid or be completely grounded. (You have a 50%

chance of picking the correct wire)

90% of

the time all the electrical problems are nothing more than

loose and dirty connections. Remove the wire connections at

the relay and the kick down switch and ensure that they are

clean. I have had to sometimes spray the components with

WD-40 and polish the contacts. Occasionally you might have

to bend the tangs of the relay cover to gain access inside

the relay to file its contact points, but this is rare. When

the kick down switch was moved to the firewall it got away

from the road splash and all the dirt on the floor that

accumulates under the gas pedal and made them much more

reliable.

As an

FYI all the electrical components for ALL Borg Warner OD

transmissions are interchangeable. There are 6 & 12 volt

versions and it seems like everybody used their own

different types of wire connections, but once the

connections and voltages match up, most any component will

work in any system. (Some systems use a strange kick down

switch at the carburetor but the basic function is all the

same) So if you need a relay or solenoid you can use one

from a Chevrolet, Rambler or Studebaker etc. Firewall

mounted kick downs would generally have to come from a

FoMoCo vehicle 1963 and up.

Heavy

mechanical repair of the transmission itself is too in depth

for this article. As a quick test however, know that a

transmission that freewheels can generally be made

operational with an electrical repair. If the transmission

does not freewheel (This can even be checked with the

transmission out of the car) then it should be assumed that

the overdrive compartment was not filled with 90 wt oil and

the planetary gears are seized. It needs to go a

transmission specialist for a rebuild.

Maintenance

Maintenance

of a Borg-Warner overdrive is easy. The mot important thing

to know is that there are TWO places to add 90wt gear oil in

the transmission. There is the normal plug/hole in the side

of the transmission but ANOTHER plug/hole is in the tail

shaft area. Fill both to the bottom of the hole with normal

hypoid 90 wt gear oil as you would for any standard

transmission. Maintenance

of a Borg-Warner overdrive is easy. The mot important thing

to know is that there are TWO places to add 90wt gear oil in

the transmission. There is the normal plug/hole in the side

of the transmission but ANOTHER plug/hole is in the tail

shaft area. Fill both to the bottom of the hole with normal

hypoid 90 wt gear oil as you would for any standard

transmission.

As

discussed above clean connections are essential for the

electrical system to function. I have a 1964 F-100 with 292

OD that I have used as a driver for over 25 years. In that

time I find that I have had to pull things apart about every

4-5 years to clean the wiring connections.

Lubing the cable

In a

functional system you will find that you rarely need to pull

the cable out while driving. You rarely ever need to lock

out the system. If you are restoring an OD equipped vehicle

you will most likely find that the cable has not been used

and is stuck. While they make replacements, the knob is not

correct for 1967-72 trucks and you can generally free up

yours with out much trouble.

The

cable must be removed completely to free it up. A big nut

behind the cable secures it to the bracket under the dash. A

1/2” nut & bolt secures the functional cable end to the lock

out lever on the transmission. The upper bolt on the

solenoid secures the bracket that holds the outer cable.

(Once unbolted, this sheet metal bracket is spread apart to

remove it from the cable) Unbolt everything and pull the

cable out through the firewall into the interior. By

twisting the outer cable you should be able to break loose

the inner cable enough to remove it. Use sandpaper to clean

all the corrosion from the inner cable. Then use a wire

wheel/brush to remove all the crud from the outer cable.

Next insert the inner cable back into the outer sheave and

spray the entire assembly with WD-40 or similar light oil.

The outer cable is composed of wire tightly twisted around

the inner cable. This design allows the oil to easily seep

inside. Work it a bit and then it should move very easily.

Adding overdrive

Overdrive can be added to any truck but you need to do it

completely.

A

complete overdrive transmission must be used. It is NOT

possible to add the overdrive component to an existing three

speed transmission. The main reason you cannot add the OD

parts to an existing 3 speed trans is the need for a

shaft/rod to pass from the gear box into the OD unit to

automatically lock out the OD freewheeling clutch whenever

it is shifted into reverse. Only gearboxes designed to be

fitted to an OD unit had this passage and internal linkage.

Potentially

any B-W overdrive transmission could be used. Excluding the

variations of using a Chevrolet or Mopar OD transmission I

will focus on Ford versions. There were only a few

variations made for all the years that OD was used. The

biggest and heaviest duty version is the T-85 with the R-11

overdrive. (The T-85 gearbox was also built as a straight 3

speed and all the gears from it will work in a T-85

overdrive case). When a case was destined to have an OD

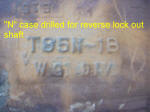

added it was identified as a T-85N (see picture) Potentially

any B-W overdrive transmission could be used. Excluding the

variations of using a Chevrolet or Mopar OD transmission I

will focus on Ford versions. There were only a few

variations made for all the years that OD was used. The

biggest and heaviest duty version is the T-85 with the R-11

overdrive. (The T-85 gearbox was also built as a straight 3

speed and all the gears from it will work in a T-85

overdrive case). When a case was destined to have an OD

added it was identified as a T-85N (see picture)

Borg-Warner

built OD units that used either 3 or 4 planetary gears. The

4 gear system is the strongest. It was identified as an R-11

unit. (see picture) These T-85/R-11 transmissions are strong

enough that they were used behind the most powerful FE

engines. Overdrive was offered behind the factory high

performance 390s and 406s in 1961-2 and the mighty 427 of

1963-4. After the 4 speed became available in 1962 request

for the OD transmission declined but it did function just as

intended by taming the very low rear end ratios that were

commonly installed in high-performance cars. Borg-Warner

built OD units that used either 3 or 4 planetary gears. The

4 gear system is the strongest. It was identified as an R-11

unit. (see picture) These T-85/R-11 transmissions are strong

enough that they were used behind the most powerful FE

engines. Overdrive was offered behind the factory high

performance 390s and 406s in 1961-2 and the mighty 427 of

1963-4. After the 4 speed became available in 1962 request

for the OD transmission declined but it did function just as

intended by taming the very low rear end ratios that were

commonly installed in high-performance cars.

The

main difference between the transmission installed in a Ford

car and truck is the design of the tail shaft. Cars used a

one piece driveshaft with a slip yoke in the trans. Trucks

used a two piece shaft with a yoke bolted to the output

shaft. The OD gears and components are all identical. If you

have a broken truck trans and good OD gears in a passenger

car transmission a rebuilder can easily open up the OD unit

and swap the necessary components to make a car trans into a

truck version or vise versa.

The

next items needed to add an overdrive are all the

accessories:

1. The relay

mounted to the firewall

2. The kick down switch mounted to the firewall and

the accelerator linkage that activates it. (although

it is also possible to use an older under pedal type

switch)

3. The OD cable and dash bracket. (and a firewall

grommet that seals the hole)

4. The wiring harness. (without a harness the wiring

harness can be fabricated by connecting the

terminals and components as shown in the wiring

diagram) {see image}

While

it seems like it might be difficult to add or repair a

factory type Borg-Warner overdrive system, once you learn

how to use the system to its maximum potential and

versatility you will find it well worth the effort. |