|

|

|

|

|

Fuel

Tank Sending Unit Tech |

|

|

|

|

Whether you're

troubleshooting your truck's fuel system to find out why the fuel gauge

isn't working (or not working accurately) or simply need to know how to

check a junkyard part, knowing what to do can save you a lot of

headaches and money in the long run. On this page I hope to give you the

information you need to know to make an accurate diagnosis of your

parts. I'm only going to be covering factory setups on this page,

however, since the vast array of aftermarket auxiliary fuel tank setups

would obviously make this tutorial an impossible task.

FYI: The most common

fuel tank used in the '67-'72 era of Ford trucks is the in-cab tank.

The standard version holds 19 gallons, those equipped with evap. controls hold 18.5 gallons,

and a

21.5-gallon version was also available.

|

Fig. 1 - These are the

two most common sending units you'll run across. On the left is the

25-gallon factory in-frame fuel tank sending unit. On the right is the standard

19-gallon in-cab fuel tank sending unit. |

THE BASICS

|

|

Even though it probably doesn't seem like it to someone who's

having problems with their fuel level gauge, these are actually

very simply electrical devices. Understanding how they work

makes it much easier to diagnose problems. Here's how the fuel

gauge works:

The fuel gage circuit consists of the sending

unit in the fuel tank, the gauge in the dash, and

the wiring and dash wiring (or circuit board) between them. As with most sensors, the

tank sending unit is simply a variable resistor. Its function is to resist the flow

of

current from the ground to the gauge depending on the position of the float

within the tank. The higher the fuel level, the higher the float raises, which

decreases the resistance between gauge and ground. The more current that flows

through the meter, the higher the gauge needle moves. |

Fig. 5 |

The sending unit operates off a 5-volt pulse supplied by the

instrument panel voltage regulator (IPVR, Fig. 5), so just

running a 12V hot wire to the unit won't work, and in fact will

fry the sending unit. See Fig. 6 for the typical

location on the backside of the instrument panel. |

|

Fig. 6 |

|

|

Fig. 7 - '67-'69 vs. '70-'72 style

regulator. The later style was for use with a printed circuit

board. (click to enlarge) |

You can test the IPVR without pulling the instrument cluster.

Tilt the seat forward and pull off the orange wire from the fuel

tank sending unit. When you probe the connector, your test light

should flash on and off. You can also do the same test under the

hood. Pull off the sender wire from the temperature sender

and/or the oil pressure sender and probe those connectors...they

should flash too. |

TROUBLESHOOTING

|

PROBLEM:

The fuel gauge does not work at all...no needle movement.

PROBLEM:

The fuel gauge does not work at all...no needle movement.

With the

ignition switch on, remove the wire from the fuel tank sending unit

and ground it to the unit housing. This removes the resistance

supplied by the sending unit, and should cause the gauge to swing

over to the 'Full' position. Does this happen? |

|

|

|

|

The

gauge and wiring are good. The problem is most likely with the sending unit. The

sending unit must be removed for further testing.

(1) |

Ground

the sending unit wiring to a good chassis ground (instead of the

sending unit housing) and watch the gauge. Does it now peg out to

the 'Full' side? |

| |

|

|

|

|

|

The

problem is with the sending unit ground. Either the unit itself is

bad or the float/arm is binding/missing. The sending unit must be

removed for further testing. |

The

power supply to the gauge has been interrupted, (check fuses), the

gauge is defective, or the wire from the gauge to the sending unit

is open or has a break in it. |

|

Testing

the Sending Unit |

|

|

After

the sending unit has been removed from the tank, check to make sure

the float is present, intact and still floats and that there

is no binding with the float arm. Reconnect the gauge wiring to the

unit and ground the unit. Move the float arm up and down. If the

gauge reads full in the full up position and empty in the full down

position, then the sending unit is good. Verify by hooking up an

ohmmeter to it and making sure it reads 8-12 ohms full and

70-73 ohms empty. If not, the sending unit needs repaired or

replaced. You can easily disassemble the head of the sending unit to

clean and/or repair...see the photos below. |

TROUBLESHOOTING NOTES

(1)

If you have dual tanks and a non-operative or sporadic fuel gauge,

and grounding the sending unit wire on each tank pegs the gauge, you

probably don't have problems with both sending units. Take a look at

your fuel tank selector switch as a culprit. Test the switch for

continuity. You might find you'll need to carefully disassemble and

clean the switch internally and lubricate it with dielectric

grease.

|

Fig.

8 |

|

For educational purposes I hooked this sending unit

up to both a digital and an analog ohmmeter to

compare the readings. Both gave similar readings and

verified that it was reading within normal

parameters.

NOTE: You MUST make sure your ohmmeter is capable of

reading the range needed...many inexpensive

hardware-store variety units are not designed to

measure that fine a range. My little analog ohmmeter

only had one range for reading resistance, which was

1-1000Ω. This scale is MUCH too great for

reading the slight variations needed here, and

didn't even result in the meter's needle moving at

all. You need a tester having a 1-100Ω or 1-200Ω

range. Having the right equipment makes all the

difference! |

|

Fig.

9 |

Fig.

10 |

Fig.

11 |

|

Measuring the resistance in the 'Full' position of the

float gave readings between 9-11 ohms. |

Measuring the

resistance in the 'Empty' position of the float gave readings

between 67-70 ohms. |

|

As

mentioned above, a fuel tank sending unit is nothing more than a variable

resistor, and the fuel gauge is simply measuring the resistance

between the hot wire and the ground.

The fuel tank sending units used on all Ford products up through

1986 have a resistance range of approximately 8-12 ohms full and

70-73 ohms empty. (I tested my factory 25-gallon in-frame

auxiliary tank's sending unit, however, and got readings of 20Ω

full and 85Ω empty.) |

|

Fig. 5 - To open the head, simply

straighten out these metal tabs holding the unit closed and

gently pull the two halves apart. |

Fig. 6 - Once the unit is opened

up, you'll see the thin wrapped wire which make up the resistor.

The thin metal wipe glides along the wrapped wires, and the

resistance is measured between the end of the resistor and the

end of the metal tang. |

Fig. 7 - Here's another view of the

exposed resistor, with a better angle showing the metal wipe

inside. This wipe can be carefully bent, if needed, to make

better contact with the wound resistor wire. Occasionally the

wipe has fallen off the shaft and can be soldered back on. You

can also gently clean the internals with fine steel wool, but be

VERY careful not to break any of the wires. |

| |

|

If you're unable to find an exact factory-style replacement sending unit

(or unwilling to pay the prices they're getting these days), there's

another option. You can simply go to your auto parts store and tell them you need a

sending unit to work with those resistance readings mentioned above.

If you can only get one which similar resistance values but not exact, you can

usually bend the float rod and/or the

tangs on the sender body to alter the resistance to suit. Most sending units

have universal flanges that will work in any tank unless it is home

made.

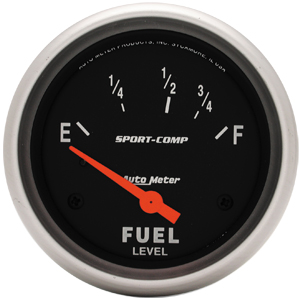

If you're going an aftermarket gauge, depending on who you get it

from, you might have to use their sending unit. Most aftermarket gauges are

not for use with a factory Ford sending unit. However,

Autometer does have special gauges which work with the factory

sending unit. From the Autometer website:

|

http://www.autometer.com/tech_faq_answer.aspx?sid=1&qid=56

The

short sweep electric fuel gauge manufactured by Auto

Meter for the Ford 73-10ohm range is calibrated for the

original Ford factory supplied, non-linear, fuel level

sender design. If you view the gauge dial itself, you

will notice that the halfway point in the gauge is in

fact not centered in the field in order for the

calibration to match this special sender. The

short sweep electric fuel gauge manufactured by Auto

Meter for the Ford 73-10ohm range is calibrated for the

original Ford factory supplied, non-linear, fuel level

sender design. If you view the gauge dial itself, you

will notice that the halfway point in the gauge is in

fact not centered in the field in order for the

calibration to match this special sender.

The Ford Fuel Level sensor with a 73-10ohm range

operates with the following ohm ranges for Full, Half,

Empty, and Below Empty:

Full: 10ohms

Half Tank: 25ohms

Empty: 50ohms

Pointer Width Below E: 73ohms

If you have replaced the original equipment Ford sending

unit in your vehicle with an aftermarket sending unit,

you may notice that the gauge will match the sending

unit at the Full and Empty portions of the scale, but

that the readings in between will not match up. The

reason for this is that some aftermarket senders

operating with the 73-10ohm range now utilize a linear

movement instead of the original non-linear scale. The

comparative ohm reading difference for Full, Half, and

Empty have been supplied below for your reference.

Full: 10ohms

Half Tank: 41ohms

Empty: 73ohms

As you can see these numbers differ radically from those

of the factory Ford sending units and have a drastic

effect upon the gauge readings.

In the event that you have this situation, we recommend

one of two options. The first would be to seek an

original equipment fuel level sending unit from Ford

directly for your vehicle. The other would be to

purchase one of our 240-33ohm scaled gauges and the

matching #3262 sending unit, or if this unit will not

fit your specific tank type, a similar 240-33ohm fuel

level sending unit from your tank manufacturer. We

recommend the 240-33ohm units because they are a broad

linear scale and provide a very accurate reading of the

fuel level in the tank. |

Ohms/Resistance

(Empty/Full) |

Popular Models |

| 0-90 Ohms |

most GM cars, 1965-up |

| 73-10 Ohms |

pre-1989 Fords & most Chryslers |

| 240-33.5 Ohms |

Industry standard, works on many

popular cars |

| 0-30 Ohms |

most pre-1965 GM cars |

| 16-158 Ohms |

most '89-up Fords |

|

|

|

|

Want to link to

this site? Please save this banner to your hard drive to place on your

webpage.

The correct link to use is

http://www.fordification.com

|