|

|

|

|

|

The Manual 3-spd Steering Column

Explored |

|

|

|

This page is a

collection of photos and observations I made while disassembling

a pair of manual three-speed (a.k.a. '3-on-the-tree') steering

columns. The photos contained will probably eventually be

incorporated into a "How To Rebuild" tutorial, but in the

meantime I decided to post these pictures just for visual

reference. |

|

Both

of the steering columns reviewed in this article have been

removed from the vehicles.

Start by removing the steering wheel with an appropriate puller,

and then sliding the main shaft out the bottom end of the

column. There will be a spring under the steering wheel holding

the upper column shaft bushing into the upper bearing...don't

lose the spring or bushing. Also, remove the spring-loaded horn

contact from the turn signal switch so it doesn't fall out and

get lost. Next, remove the turn signal stalk, then the shift

handle (by driving out the retaining pin) and finally the three

Phillips-head screws holding the turn signal retaining plate

(Fig. 01).

Next, you'll need to remove the turn signal switch. Because the

wiring is snaked up through the column, and the plastic harness

connectors are too large to pull through, you'll have to remove

the connectors. You do this by using the yellow-handled tool

(Fig. 02) to release the small prongs for each wire and remove

all wires from the connector. But first you need to make a

careful inspection (and take some notes) about the proper

orientation of the wires, so they can be replaced in their

respective positions during reassembly. Pull the turn signal

switch up and out of the column.

Next, use a 7/16" socket to remove the two nuts holding the turn

signal housing from the column housing. When you go to lift the

turn housing away from the column housing, be sure you don't

lose the two bolts. The heads of these two bolts are just barely

hooked into holes in the end of the column housing, as shown in

Fig. 04. Also shown in Fig. 04 and marked with a yellow arrow is

the end of the shift tube, as it extends up through the shift

collar.

Next, make a schematic of how the shifter arms at the base of

the column are arranged, and then you can slide the shift collar

and shift tube out from the main column housing. (The shift tube

is actually separate from the shift collar, so it's possible

it'll slide off the tube first, and then you can grab the tube

and pull it out.) This in turn will release the two shifter arms

at the base of the column. You'll notice that there is a thin

plastic thrust washer on each side of the shifter arm pack, as

well as a thicker plastic spacer between the two shifter arms.

Pull the two shifter arms out of the column, along with the two

thrust washers, and then rotate the thick spacer around 90-degrees so

that it can be removed from the main column housing. The spacer is flat on two sides to allow for easy

installation/removal and must be spun for clearance to remove

(Fig. 8). |

Fig. 01 - I've removed the three screws holding the turn

signal switch.

Fig. 02 - Use the yellow-handled tool to release the column

wiring from the connectors.

Fig. 03 - Remove these two nuts and remove the column

spacer.

|

Fig. 04 - Shown are the two bolts holding the turn signal

housing to the main housing. The yellow arrow shows the end of

the shift tube. |

Fig. 05

-

Here is a close-up of the shift arm configuration. The

green arrows indicate the welded-in housing spacers,

between which everything else fits and are not

removable. The yellow arrows point to the thin plastic

thrust washers on each end of the shifter arm pack. Note the lip

on each of the thrust washers that grip each respective

shifter arm. The orange arrow points to the thick

plastic spacer between the two shifter arms. Once the

shift tube is slid out the top of the column, these will

be loose, so remove them carefully, paying attention to

the proper orientation of the spacer and each thrust

washer. Fig. 05

-

Here is a close-up of the shift arm configuration. The

green arrows indicate the welded-in housing spacers,

between which everything else fits and are not

removable. The yellow arrows point to the thin plastic

thrust washers on each end of the shifter arm pack. Note the lip

on each of the thrust washers that grip each respective

shifter arm. The orange arrow points to the thick

plastic spacer between the two shifter arms. Once the

shift tube is slid out the top of the column, these will

be loose, so remove them carefully, paying attention to

the proper orientation of the spacer and each thrust

washer. |

|

|

|

Fig. 06 - Here are the shifter arms,

thrust washers and spacer in the correct orientation. |

|

|

|

|

Fig. 07 - Here are the two thrust

washers. I have one in place on a shifter arm,

and you can see how the lip of each shim

fits snugly over the end of the shifter arm. |

|

|

|

|

Fig. 08 - Here is the thick spacer.

I'm holding it as it would be oriented

inside the column housing. To install, you

turn it 90 degrees clockwise, insert it, and

then spin it back 90 degrees. |

|

|

Here

is a shot of the setup on a different column, showing the

shifter arm pack on the end of the shift tube. You can see that

the bottom thrust washer is broken. The yellow arrow points to a

plastic sleeve which is slid over the end of the shift tube.

With all the plastic pieces in this setup, you can definitely

begin to see how these wearing out will cause the shifter arms

to become loose and unstable, which could cause difficulty in

shifting and possible binding. The shifter arms are held

laterally stationary by the column housing spacers, and the

shift tube slides back and forth through the arms, engaging each

one with a tab mounted onto the end of the shifter tube. |

Fig. 09 |

|

This

is a close-up of the tab on the shifter tube that actuates the

shifter arms. The spring holds the tube engaged

with the short shifter arm, which is the 2-3 (2nd-gear/3rd-gear)

arm. When the shifter handle is pulled toward the driver, it

pivots in the shift collar and pushes down on the shifter tube,

over-riding the spring. The tab will disengage from the 2-3 arm

and engage the longer R-1 (Reverse/1st-gear) arm. You can also

see the plastic sleeve on the end of the tube. |

Fig.

10 |

|

In

this picture, I've slid the short 2-3 arm back on the shift tube

without the plastic shim. You can see how the metal tab on the

shifter arm engages the arm. When a driver pulls the shift lever

towards himself to shift into Reverse or 1st gears, the column

is pushed down through this 2-3 arm (and the thick plastic

spacer) enough that the metal tab no longer engages it, but

instead engages into the longer R-1 arm beneath it. At this

point the spring is almost fully compressed. |

Fig.

11 |

|

The

yellow arrow in Fig. 16 is pointing to a section of the thick

plastic spacer. See where it's worn into a 'ramp'? Compare it to

the other and you can see it's not supposed to be like that.

This would have been caused by the shifter lever not being

pushed all the way down when shifting into third gear, causing

the spot-welded tab to 'catch' the edge when shifting from

second to third gear. |

Fig.

12 |

|

OK,

let's head back up to the business-end of the column. The other

end of the shifter tube slides into the shift collar. There is a

metal tab welded onto the top end of the tube that engages it to

the collar, and as a driver is shifting, the tube slides up and

down in the collar. In Fig. 12, however, you can see how the

shift tube tab has come loose...it's no longer attached to the

tube. However, because of the semi-tight fit, it still

shifted...although it was very sloppy...and it was a major PIA

to slide the tube out of the collar. I ended up having to drive

it out from the top. |

Fig.

13 |

|

...and here's the carnage. The hole in the right side of the tab

is supposed to line up with the hole in the end of the tube.

It's this hole that the shifter lever fits into to move the

shift tube up and down. Therefore, the tab not only keeps the

tube engaged with the shift collar, but provides some extra

support for the thin shift tube, to minimize damage from the

shift lever. You can see how rounded-out the hole in the shift

tube is, since the tab was no longer reinforcing the hole. The

tab has a very short tang on the bottom side which fits into the

pilot hole (orange arrow) and is then spot-welded to the tube

(yellow arrows). However, when the two factory spot-welds broke,

apparently the previous owner decided to weld it back in place

at the end of the tab, but in doing so completely burned through

the tube (green arrow). And the weld wasn't any good anyway,

since it obviously broke again afterwards. |

Fig.

14 |

|

The

yellow arrow in this shot is pointing to the groove in the shift

collar that the tab is supposed to ride in. You can also see the

hole through which the shifter lever extends to engage the

shifter tube. The tube rides up and down in the close confines

of the collar as indicated by the orange arrow. This area needs

to be lubricated for smooth operation of the shift tube. |

Fig.

15 |

|

Here's a comparison shot of the bad shift tube and a good one,

with the tab still attached with the factory spot-welds. |

Fig.

16 |

|

It

was very obvious to me that both of these 3-spd. columns had

been disassembled by previous owners. This shot of a VERY worn

column shaft couldn't have happened with a 3-spd column, since

the shaft is inside the shift tube, and the tube would have worn

out first. This could only have come from a 4-spd

manual-steering truck that didn't have a shifter tube, and would

have been caused from bad front cab mounts which let the cab

sink down in front, putting pressure on the bearing. The bearing

would have eventually worn out, and then the shaft would have

started to ride on the bearing housing, causing this wear. |

Fig.

17 |

|

|

|

Replacing the Upper Column bearing |

|

I

decided to try pressing out the upper column bearing, just for the

practice. I figured it could be easily pressed out with a large

C-clamp, but after spending nearly 30 minutes unsuccessfully looking

for mine in the shop, I decided to just use the bench vise, which

worked beautifully. Just be ready to catch everything, because once

the bearing pops out, everything will hit the floor. I actually

ended up denting this housing when it landed on it's side, but

fortunately this was just a trial run and this particular piece just

gave it's life for the educational aspect. |

|

Fig.

18 |

|

Here is the turn signal housing, with the pressed-in

bearing, along with the steel column bushing. |

|

|

Fig.

19 |

|

Clamped this up in the bench vise, which worked great.

The 2x4 was to keep the jaws from marring the housing. |

|

|

Fig. 20 |

|

...and here's the newly-removed bearing. |

|

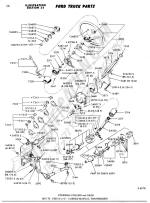

Exploded-view Schematics

(from

the Ford Master Parts catalog) |

|

|

|

Steering Column

and

Gear

(with 3-spd manual transmission)

1966-1972 F250 (4x4)

1024

x 1386, 125K |

|

|

|

|

Steering Column,

Gear and Wheel

(3-spd and automatic)

1965-1972 F100/F350 (4x2)

1967 F350 (4x2)

1024 x 1359,

194K |

|

|

|

PARTS NECESSARY FOR REBUILDING

SOURCES:

Macs Auto Parts,

EarlyFord.com,

Dennis-Carpenter.com,

CarolinaClassics.com |

|

Column Shift Arm Spacer

(Fig. 8 above, orange arrow) |

'65-'71 |

C9TZ-7336-A |

$3.95 ea |

|

'72-'79 |

D2TZ-7336-A |

$3.95 ea. |

|

Column Gear Shift Arm Thrust Washers

(Fig. 8

above, yellow arrows)

(2 per truck) |

1965-79 F100/250, Bronco |

C5TZ-7D363-B |

$2.00 ea. |

|

Gear Shift Selector Arm Bushing

& Insulator Kit

(located on the ends of each of the two shifter arms, as seen in

Fig. 8) |

'65-'72 F100/250

|

C5TZ-7343-A |

$16.00 kit |

|

Shift Tube |

'61-'77 |

|

$50 - $60.00 |

|

Upper and Lower column

bearings |

'64-'72 |

|

$6.00 |

|

Upper bearing sleeve |

'53-'77 |

B1AZ-3518-A |

$4.50 |

|

Shift collar for standard shift |

'61-'77 |

|

$38.00 |

|

Steering column tube flange

(picture courtesy of

Macs Auto Parts) |

'66-'72 |

C5DZ-3511-A |

$29.95 |

(pictures courtesy of

CarolinaClassics.com

unless otherwise noted).

CarolinaClassics also has a complete column rebuilding service.

I've

been unable to locate a source for the plastic sleeve located at

the base of the shifter tube (as seen in Fig. 10). In fact, it

doesn't even show up on the exploded-view diagrams above. If you

have any info on this piece, please

e-mail me. |

|

|

Want to link to

this site? Please save this banner to your hard drive to place on your

webpage.

The correct link to use is

http://www.fordification.com

|