I got a used windshield out of a truck at a local scrapyard for $50. At this point I am pretty happy because brand new they are about 175 plus tax here. I also got a new seal from NPD (made by Precision Replacement Parts), with the groove for the stainless steel trim around the windshield.

We (my dad and I) tried to put the rubber on the glass when the rubber was at room temperature, and that ended after 45 minutes with a decent amount of swearing and sore fingers. After that failed attempt, we set it by the fire (but not too close) for a while, and that made the rubber much more pliable. The problem we ran into next was that the groove in the rubber is about 1/8” narrower than the glass, so whenever we got a section on it would just pop off again. We didn’t want to tape it because then when it came time to install the glass on the truck we would need to peel the tape off the rubber, risking pulling the rubber off again, or at least allowing the rubber to be pulled off if we accidently pull on it. Here is our solution:

Start with a piece of tape:

Add a second small piece in the middle so there is no sticky side there:

And now you can use that to tape onto the glass, wrap the non-stick portion over the rubber, and tape onto the other side of the glass.

We repeated this as we got more rubber on the glass; about every 6” or so.

After leaving that for a few days, the rubber seemed more willing to stay on (I guess it had stretched enough), so we started putting the stainless steel trim into the groove. I don’t think it matters, but we started with one of the side pieces and then the bottom, other side and top. As we went we removed the tape strips, put in the trim and reapplied the tape (really REALLY didn’t want that rubber coming off when we install the glass).

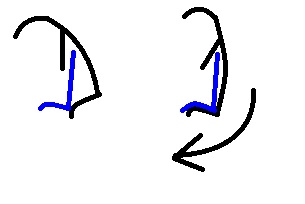

To get the trim in, you need to get a lip on the rubber under a lip in the trim:

Some sections would go on easily, and others were tougher to do, so we used the specialty Ford tool in the above picture to press the rubber lip under the trim lip.

Here is another view of the specialty Ford tool. I will be selling these for $20 plus shipping if anyone is interested :

Now it came time to actually install the windshield. You need to run a drawstring (I used 1/8” rope) in the groove behind the flap of rubber that will be on the inside of the window (sorry I didn’t get a pic of this, but you can figure out what part that is I’m sure). Start at the bottom in the middle, run it all the way around and overlap the ends by a couple inches. Then tape the rest of the rope to the inside of the glass so you don’t have to worry about it being on the right side of the glass later on.

Now here is something I can’t stress enough: lubrication is very important. We used dish soap and water in a spray bottle. Spray this mixture into the groove where the rope is until you think it is all soaked, then spray some more. This helps a lot in the final part.

Get two people to place the glass onto the truck, and one person inside to look at the seal and get the window centered.

Once it is centered, the people outside should apply gentle pressure in the middle of the windshield. Begin pulling out one of the ends of the drawstring. It should pull that rubber lip over the metal lip on the cab fairly easily during the straight stretches.

When you get to a piece of tape, the person inside should slice it and someone outside can then slide it through (remember it is not sticky in the middle? This way you can keep everything taped on even as you install it, and remove the tape at the very last moment).

In the corners it may get tough to pull the rubber through, so remember the words of the late, great Frank Zappa: “[when pulling the drawstring on the windshield rubber of a bumpside Ford, always use] a vigorous circular motion hitherto unknown to the people of this area…here it goes, the circular motion”

Yes, that drugged-up rocker had the right idea. If you find it hard to get the rubber over the metal lip, try moving the rope in circles as you pull.

When you get to the top of the first side you do, start on the other end of the rope. It is easier to get the top on when the bottom is on all the way across. When both ends of the rope are on the top, get someone to hold one end as you pull the other or else you will just pull the rope through and the rubber will not be in place.

When you are done all the way around, give the window some more pressure all over to make sure it is seated well (but not too much, it would be a shame to crack it now!) and make sure the rubber is seated all the way around on the inner lip. When you are done, and there are no cracks in the glass, stand back and admire your handiwork.

Congratulations, you just saved a bunch of money and learned a new skill! Unless you broke the glass in the process, in which case the recommended treatment is 6-8 bottles of beer per day as long as the feelings of shame and self-loathing persist.

I hope this helps a couple people install their own windshields, or in their decision to get a shop to do it. It isn’t that hard, just be patient and don’t be rough on the glass. I’ve heard some people say they did the whole process in 45 minutes for both front and rear window, so the level of difficulty may depend on the seal you get. If I can do it, so can you…