http://www.ford-trucks.com/forums/12052 ... build.html

Moderator: FORDification

1/2 inch flat stock that I hand bent and welded to the plate with the f600 face bonded in and seam sealed to make it look as one. I think there are pics in the attached thread.IN2FORD wrote:I thought that looked like an F600 dash. I have one I thought about modifying for aftermarket gauges. So how did you make the edge around it?

Barry

I agree with you on the transmission comment. Disagree about the turbo comments.averagef250 wrote:I skimmed your FTE thread, didn't have time to read it all.

Nice, clean work. You have great attention to detail!

I like it when people give me their perspectives and criticisms, so I thought I might do the same for you here. I have a little experience with 4BT's.

You will never get 35 MPG average. If you have all the right magic bits in your engine you might get high 20's at 65ish MPH cruising. By magic bits I mean 7163 pistons, matching injectors, .16mm initial pump timing and a very efficient turbo system. By very efficient turbo that would be a 40-44mm HX30 or a later H1C.

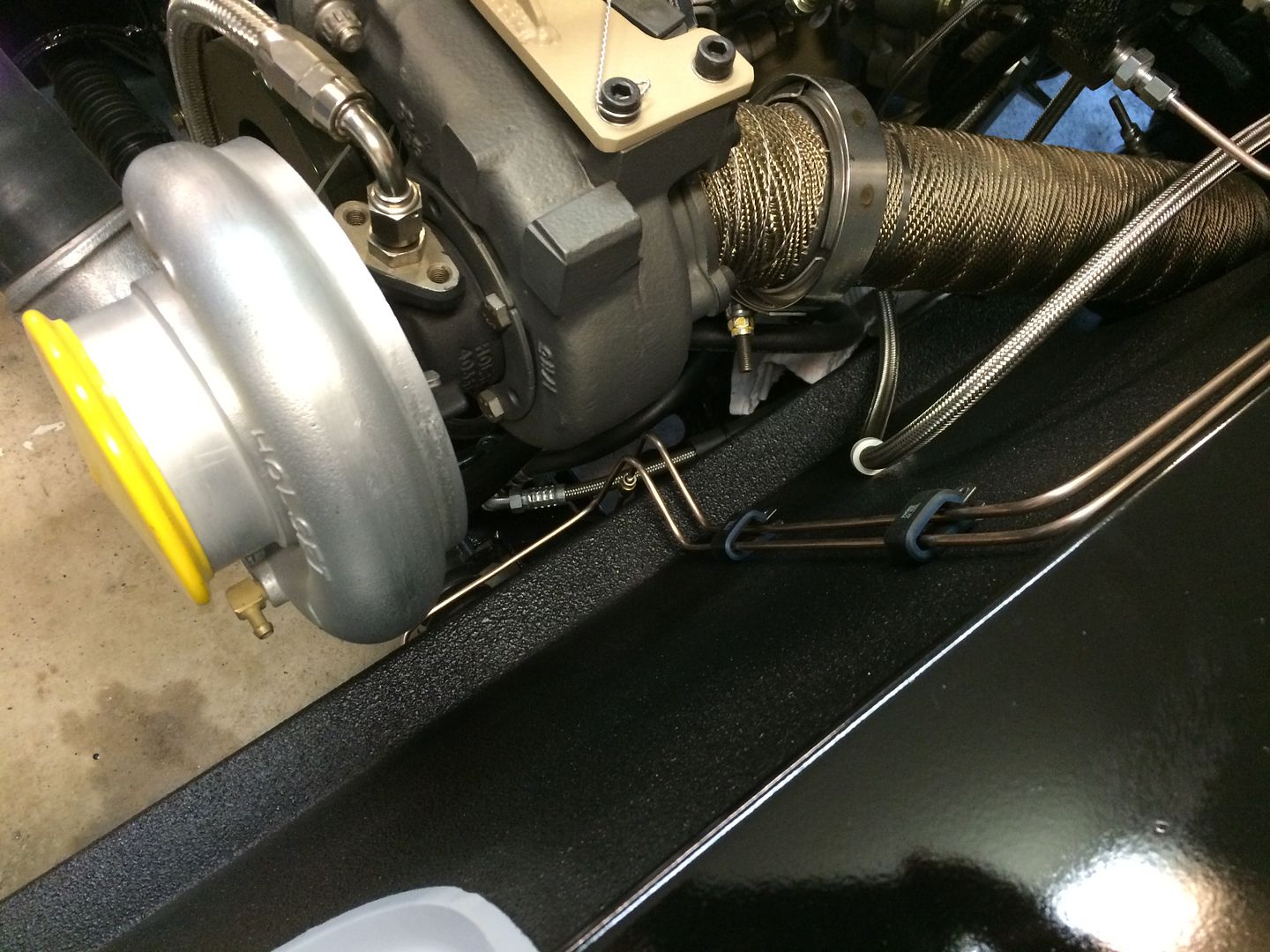

I really appreciate the fabrication you put into your turbos. It looks great. However, you have a ton of bends and restrictions there and you are using the wrong HX30. That is the agricultural/industrial HX30. It has the wrong compressor on it for a peppier engine. It's made for 100 HP and not enough compressor to run on a road engine. I don't know what kind of HX35 you are using, but the 7 blade later model HX35 works pretty good as a hot single on a 4BT as long as you are OK losing a few hundred RPM's on the bottom and a little smoke to light it. I would recommend an HX30 and HX40, not the 30 and 35. The 30 and 35 are too close. They are almost the same thing depending on which variant of each you have.

You are going to lose some efficiency with all those bends in there.

Your air filter looks very restrictive. If it isn't then it's not filtering and you'll dust your rings and ruin those turbos.

It looks like you're using hydraulic mounts. Be aware those let the engine move around A LOT! Make sure you have a lot of clearance around the top of the engine and all your plumbing can move all over the place.

If you spent $10K on the baddest 700R4 ever made with billet everything and assembled by a 700R4 god somewhere you can still fry it in 20 minutes with a 200 HP 4BT. The 700R4 has physical torque-at-low-rpm power handling limitations you cannot overcome. It will not hold up and likely will never really shift right either. If you run the 700 DO NOT RUN A SUPER LOW STALL CONVERTER! Run a sloppy converter like a bone stock 350 truck one. That will give it a fighting chance because it won't see any real torque until 2000 RPM where it can actually handle it with those fancy billet parts. Every transmission builder will guarantee you they can build you a 700R4 that will handle 1500 HP and your 4BT is no problem. Guess what? They have no idea what effect 500 lb/ft at 1600 RPM has on a 700R4 with the front pump only spinning- Guess what - 1600 RPM because they've never seen it in any other application before.

I'd highly recommend a 47RH with a compushift controller for OD and LU or a 4R100 You will be so much happier with an electric auto or a stickshift. Entirely hydraulic autos like the 700R4 are terrible behind 4BT's. They never shift properly. A 47RH will take anything you can throw at it and then some and throw you through the seat doing full locked 3-4 shifts at 40 lbs boost.

Converter- The 4BT has the balls to blow through almost any GM 700R4/4L60E/4L80E based torque converter. They just aren't really big enough if you're actually making decent power. If you go with a Dodge auto you have limitless converter options which make a HUGE difference in driveability.

FYI if you do end up being horribly dissapointed in the 700R4 and remembering this thread and switching it out for a 47RH- Dodge converters are sold standard by most converters with a modified stator and modified fin angles as a "low stall towing converter". You don't want this with a 4BT. The stall speeds are graded usually as S1.S2,S3 for Dodge diesel converters. You want the bone stock S1 converter for any 4BT. Don't let them tell you otherwise. For a hotter 4BT get an S1 converter and have a converter shop rebuild it with a billet face and triple lock clutch leaving the fins and stator alone.

If you ditch the auto the Ford M5R2 would be awesome in your truck with some 3.00 gears.

These are just my opinions. Things I've picked up in a few dozen 4BT conversions and being involved in thousands of them to some extent. I hope some/all of it is helpful.

Ranchero50 wrote:Interesting build. I no longer do FTE since they acted like douche nozzles a couple years ago so please keep the updates here as well.

On my Cummins swap with the 47rh in stock form it's held up well with a lot of weight behind it. I went with pressure switches to run OD and lock the converter. The shift is effected by the fluid temp so it goes into OD early when cold but otherwise has been reliable.

It's a crying shame you decided to notch the firewall and tucked the engine under the cowl. I really hate to see that as it creates so many other compromises inside. I was able to fit a 6bt in that space without cutting the cab and I think I have enough room to do over / under compounds if I felt the need. I did have to lift the cab 1.5" to clear the 2wd cross member. I will say that having the engine exposed has been a great help when working on it, thus the crying shame down the road when you are cussing that decision.

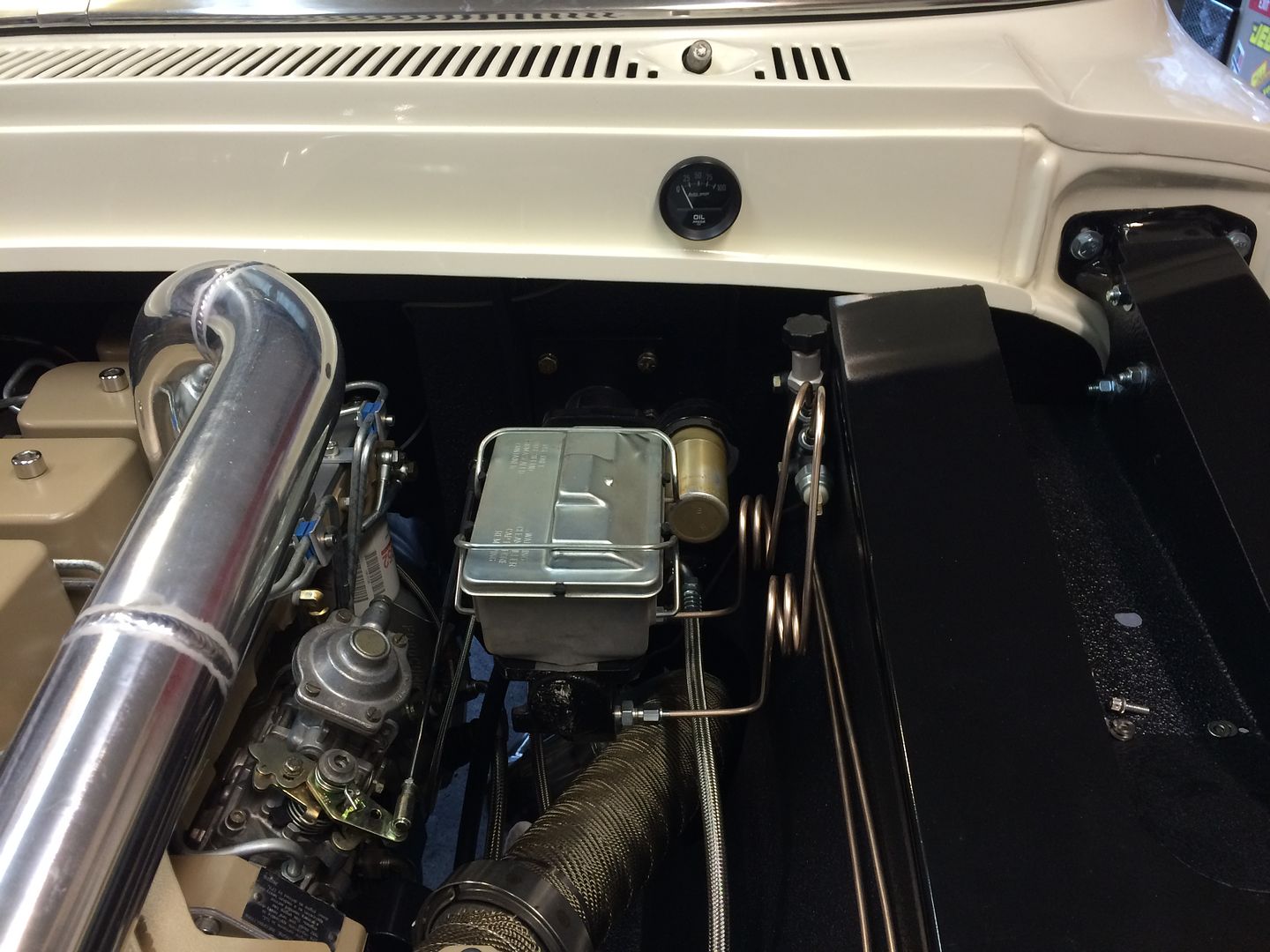

I'd also suggest rerouting the brake lines away from the hot side of the turbo. Things might get exciting in a bad way after running it hard.

ahawks9er wrote:Woah! Sweet build. Love the Detroit Steel Wheels.