That's the only pic i have of it currently. I'll try to take some more. The missing hubcap and original wheel is in the bed with a blown tire on it. It has 302, 4 on the floor with the granny gear, MS, MB front drums. You have to be a total he-man to drive it. In fact I was he-manning a u-turn the other day and felt a little pop where the spline connection between the steering gear box and the steering column came loose in a cloud of rust. The truck straightened out and I kept incredulously and meaninglessly rotating the steering wheel and almost drove through my neighbor's front yard. So it has no steering. I was planning on doing the front end swap for PS, PB anyhows, so no biggy.

I found a place for the steering/suspension/brakes that insisted on pulling parts themselves, which has its plusses and minuses. The plus is less work, the truck was basically half in a swamp. The minus is they cut stuff that they shouldn't, like the brakeline bracket on the steering box, give you all the bolts in a giant cup all mixed up, and if you're a noob like myself, you have no memories of how stuff went together to wrap your mind around, and some important hard to find stuff will probably turn up missing like brackets and bolts. Anyhow this is what i got from them off a 79 F150:

and

One of those pics is upside down, so you might get vertigo. Again, if i pulled it myself i would have left the bolts hand tight in the pieces they go in, or at least vaguely remember how they go. From looking at a thread HIO is doing somewhere im knowing that im missing some brake line frame brackets at the very least so far. Ah well, i didn't have to spend 2 hours minimum in a swamp fighting skeeters and wasps so i'll stop complaining now.

Here's a couple of action shots taking the front suspension apart:

It took about a 3 foot pipe and some serious ass to get the RA bolts off.

And now it basically looks like this:

I wound up taking the spindle/ibeam connection to a shop and having them separate them. One of them was almost totally frozen. You can see in the pic the black kingpin coated with what is basically resin. What's good there? Scotchbrite? It's basically like caramelized grease. I also brought them the rotors which they turned for me. I'll be happy if they are still thick enough.

So one of the ibeams is bent like a muh. I looked on the 70 and it's bent too, but maybe not like that. I suppose it's bent since the ibeams are one in front of the other but the wheels got to be in line. But uhm, woh:

I'm going with it though. The twist or camber to it or whatever is the same as the other. I'm thinking whatever bend you got between where the RA attaches and where the frame attaches doesn't matter, just the angle from the RA attach point on out matters, and that distance isn't really that great, so i pretty much just rationalized that away!

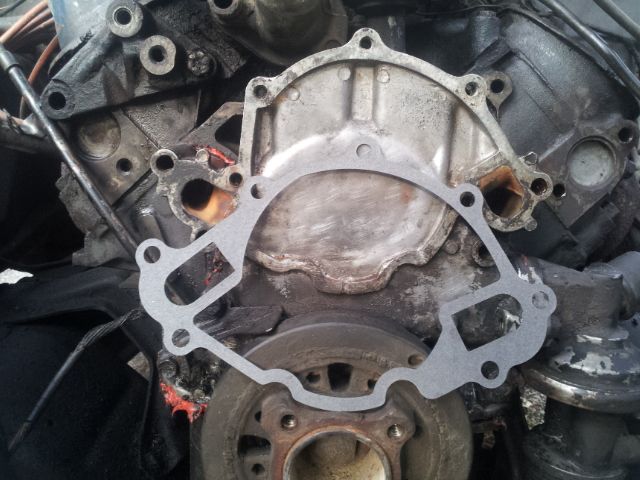

I've got an electro vat going and it is slow going. Too bad the first thing I did was the coil springs and then learned the process ruins them for spring strength. I'll just reuse the ones from the 70. Here is the master cylinder wallowing in its own putrid filth:

I bring up electro, because i have a noobish question. I want to dunk the spindles in the vat. The brass sleeves are still in them which im thinking isn't a big deal, but maybe water can get and stay in between the iron and brass? Anybody ever been there done that? There is also some kind of bearing/washer type thing still on it that spins in a gritty kind of way. I'm sure chilton's will say something helpful like "remove" this. I don't want to screw anything up. Can i just dig it off with a flathead and/or a hammer or is there some kind of trick? I got it pointed out here:

Like i said, im a noob, but not a total and utter noob, not that there is anything wrong with that. I used to wrench on a 78 mustang 2 a lot way back like 20 years ago, out of necessity. That model's relationship to old ford trucks is ironic to me now. This is my first major automotive project since then. I'll be asking a bunch of questions, most of them even ones that i'm not too lazy to research first! Any help is very greatly appreciated. Not sure if i need to ask them in the appropriate section though. I will have more material to post. The "explosion" in the thread title will surely refer to project scope explosion as much as anything else!

Thanks yall !!!