One big advantage a NP205 has over a D24 transfer case is the NP205 has a support strut to keep the t-case from slinging back and forth. If you have a D24 you probably know what I'm talking about. When under load or you give it a good amount of gas the D24 will swing back and forth doing no good for any of your drivetrain. I have a Cummins and 37's so I'm sure it's even worse for me.1971ford wrote:Struts are done. Should be able to grab the hardware for them tomorrow.

PM me with your information (Name, Address) to claim yours, I'll give you my paypal email, and once I receive $75 I'll get the strut "kit" on its way!

[ Image ]

I was asked to leave one unpainted

[ Image ]

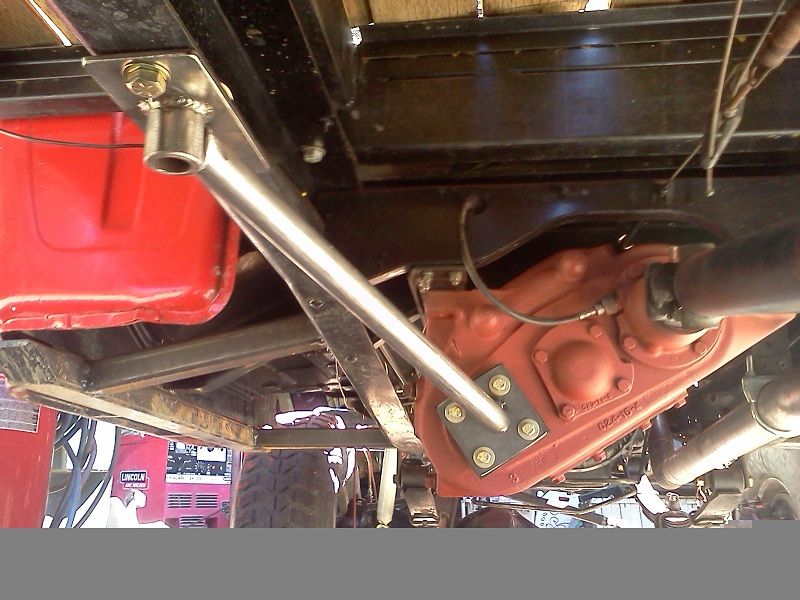

I took each strut assembly and bolted it in my highboy to be sure they are all ready to rock. Here is mine bolted in for good.

[ Image ]

So if you don't have the money or desire to swap to a NP205 right now, like me, how about supporting the D24, like the NP205 is?

Right now I'm making 2 supports. 1 for me, and 1 for someone else. If there are others thinking this is a great little investment I can whip up many more. They bolt on top of a factory bearing cover on the D24. Just remove the bolts, install the strut with longer bolts in same location, then drill two holes on the bottom of the frame for the frame-side of the strut. Haven't gotten that far yet, but that's most likely what's going to happen.

This strut utilizes a thick piece of rubber in between two 3/16 plates to keep the transfer case rubber mounted. Also if you're going to add the strut I would definitely swap out the t-case bushings at the same time. This strut will help those new bushings live much longer as well.

I will have pictures up later today of one of these things. Sound like something you'd be interested in? Not sure on what the cost would be quite yet... but not a whole lot. I can lock a price down later today after I finish one. A guesstimate right now would be $70 shipped with the strut (painted black), plate, rubber, and replacement grade 8 bolts for t-case and frame. to anywhere in the US. Installation should be fairly easy (hardest part would be drilling two holes) and should be less than 30 minutes.