The right door had been changed before and could not be raised high enough to get the bump to line up without the window frame hitting the cab frame.

Removing rear section for final trim.

Here is a picture of the surface rust on the roof header panel. Now this truck is a pretty clean truck as far as rust goes. It’s evident that Ford didn’t do much for rust prevention in 69’. I can imagine what some of your trucks look like that live in rusty country.

Loose rust cleaned off and coated with POR 15.

POR 15 soaked through the seams of the door frame.

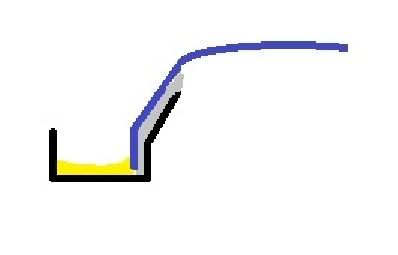

Extension welded on rocker panel to better fit to the lock pillar reinforcement on the Bronco side.

Up Next, Glued on roof.