Good day FoMoCoGuy and Robert, thanks for your great replies!

fomocoguy wrote:Sooooo, when do you plan on calling PU? The suspense is already killing me...

Thanks for being interested! I have a head cold at the moment and need to compile my main points before contacting them, but it will be this week for sure. You guys will be the

first to know what their response is!

DuckRyder wrote:Tom is very good at explaining things, at least it appears so to me. He's very patient and you can see he cares about what he does. The enthusiasm shows through.

Indeed! You should have seen the look in his eyes when he was reviewing all the camshaft options with me. He said, "I love doing this," and he looked like he was unwrapping a model train set on Christmas morning!

DuckRyder wrote:

robroy wrote:

[*] Using the 428-sized pistons, the engine will have 406 CID.

A good number, no replacement for displacement and all of that...

Excellent! This reminds me that I heard from Tom that when an engine bore is increased, it can make the engine more difficult to cool. I also heard that in this situation it wouldn't matter very much (I'm guessing because the FE engine simply has a lot of "meat"). What are your thoughts?

DuckRyder wrote:

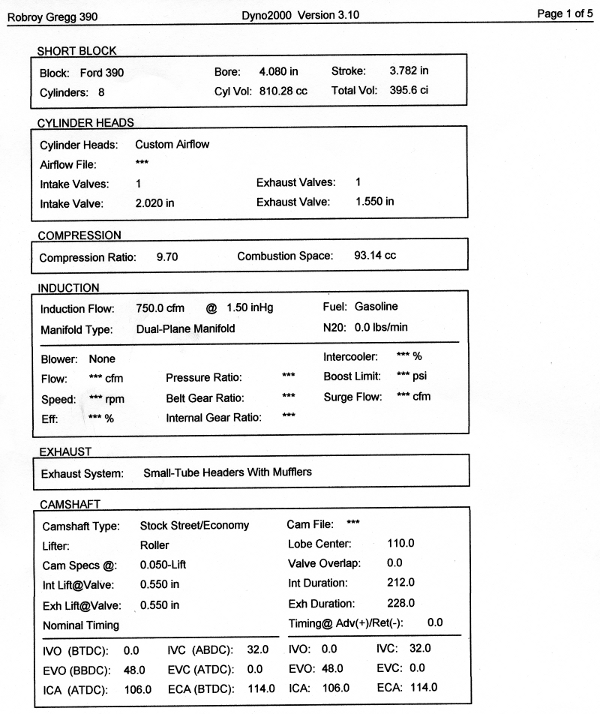

robroy wrote:[*] Tom would like to build the engine with 9.7:1 compression. He likes this ratio because there's a little room for carbon build up before the compression gets so high that detonation becomes a real problem (on high octane pump gas).

Should be good, depending on the cam and ICA (Intake Closing Angel) will probably take pump premium. I am sure Tom will tailor the static to the cam to get a street-able Dynamic Compression Ratio.

It looks like I have some reading to do before I'll understand these terms (other than "pump premium"

), but I'm also sure that he'll take tremendous care with the specifications!

DuckRyder wrote:robroy wrote:[*] I asked Tom about what main upgrade came to mind, if I were going to spend a little more cash than his initial build idea. Tom said the #1 upgrade would be a roller camshaft and lifters!

I agree whole heartedly, a roller cam can make a bigger cam "act" like a smaller cam.

I heard this same thing from Tom! In fact, when he heard from me that I was ready for the roller camshaft setup, he increased the aggressiveness of the camshaft lobes in Dyno 2000 to suit.

DuckRyder wrote:The roller lifters decrease friction and drag in the engine and live better with current off the shelf oil.

This I like very much. When an upgrade can increase both performance and

reliability, it's well worth an extra $700 to me!

DuckRyder wrote:You heard Tom reference the "additive situation" several times. Once the break in of a flat tappet cam is done its less prone to fail, but they can and do fail in use and the oil situation only makes it a greater possibility. The more radical the cam, the more risk.

Quite interesting! Yeah I've very glad Tom mentioned the roller camshaft configuration--it sounds like a big improvement for the engine.

DuckRyder wrote:robroy wrote:[*] Based on Tom's advice, we agreed that I'd go with a Crower roller camshaft (I forget which brand he recommended for the lifters, but naturally they'd be selected to match the camshaft).

We have talked a bit via PM about this, Crower is a great cam, and I feel the roller is the way to go particularly with HIPPO (HIgh Pressure Pin Oiling). Let let Tom determine the grind based on your application.

Fantastic! I still need to read the article you sent me (thank you very much for that)!

DuckRyder wrote:robroy wrote:[*] With low RPM torque in mind, Tom recommended selecting a Crower grind that will result in a mild "muscle car" type of idle at around 650 RPM.

Sounds appropriate...

Yes I think so. Of course as you know, my lack of experience with different types of engines influences my desires here a lot. The only vehicles I've ever driven that had fast idling engines also happened to have funky/broken engines. So I've never experienced the fast idle situation with a super healthy engine (an engine made that way on purpose).

DuckRyder wrote:robroy wrote:[*] I heard from Tom that unlike their flat tappet camshafts, the Comp Cams roller camshafts are OK.

Can you expand at all on this, it sounds like Tom might not care for Comp flat tappet cams (Like me), did he have bad experiences?

If I remember correctly, I did hear Tom voice disapproval of the Comp Cams flat tappet camshafts, although I don't think I asked him for any anecdotes (or I've already forgotten--sorry)! This said, I will definitely be recording more video of Tom's wisdom before this adventure is complete, and I could ask him specifically about this.

DuckRyder wrote:I really do like Crower, I believe they are still family owned and not part of one of the huge conglomerates, I like that!

Excellent!

DuckRyder wrote:robroy wrote:[*] ARP head bolts will be used. The engine already had ARP connecting rod bolts, so those can probably be re-used.

Again, very good choice.

Great!

DuckRyder wrote:robroy wrote:[*] With regard to accessory bolts, I declined Tom's offer to use ARP bolts for those too, since they're more of a cosmetic item there (I'm guessing). Do you think I made the right choice?

I have mixed feelings, they don't cost that much, the reduced heads can help access in places. It can probably be argued they provide more consistent torque. New bolts may be less apt to fail. I'd probably use them (what am I saying, I did use them).

I see! Yeah I'm not trying to save cash on this specifically--I just didn't understand what meaningful benefits they could provide. The accessory bolts were supposedly brand new from Proformance Unlimited's build, yet you're right about the cost being pretty small. If there are indeed benefits (beyond cosmetics) to doing so, I'll go for this without hesitation!

DuckRyder wrote:

robroy wrote:[*] I asked Tom about stroker kits. He said that although it would increase the performance potential a lot, it would also add an extra $2,000 on to the price tag for the engine.

Since the rods appear good and it sounds as if the crankshaft will polish (polish and turn is a distinction) this becomes a matter of Cost/Benefit ratio, more CID is more displacement. If the 390 crank will simply polish up, then thats a minimal investment. If it requires turning to the next under-size, then a slightly larger investment. Some people feel that going .020 or .030 under on a crank weakens it, I think that is a non-issue here. I do wonder if Tom might have access to a 428 crank core to me a 300-400 additional investment to go to standard 428 would be worth it. (you'd have to change the flywheel too though).

Thanks for giving me your thoughts on this! I could ask Tom about whether or not he has a 428 crankshaft. I might hesitate to do this though, because if the 428 crankshaft did cost around $350, and the flywheel around $250, it could start to add up. After all, I already own a brand new Centerforce 390 flywheel. But I will ask Tom--thanks very much for this suggestion!!!

Also thanks for letting me know about the big distinction between simply polishing and

turning a crankshaft. I wasn't fully aware of this! I'll re-watch the video of Tom discussing the crankshaft to get more clear on what he had in mind (one of the great benefits of those videos)!

DuckRyder wrote:robroy wrote:[*] I asked Tom about the Edelbrock aluminum heads.

I'd go with Tom's preferences here. I was glad to see the air cooled head being CC'ed in the video (what was that, Lycoming, Continental or perhaps Porsche?).

That was a Porsche head (he discussed it with another customer who stopped by)!

DuckRyder wrote:He has the greatest experience with FE's and he knows what he can do. I don't know what I saw now, but I was thinking that PU had already put intake seats in and had machined them too deeply, which would get into welding to fix and so forth. I hear Tom talking about going with CJ sized valves, which should take care of the seat issues.

Indeed, he'll be using over-sized, stainless valves. Last I heard that would be part# 2090165 (are these CJ sized valves)? I also noticed that he used the CJ valve strategy on HOWDY69's 410 (416 actual CID) engine.

About what was done to the heads by Proformance Unlimited, I wasn't entirely clear if they'd machined the seats too deeply, or if the seats hadn't been freshly machined. Maybe I can understand more about this by re-watching the "Heads" video.

DuckRyder wrote:

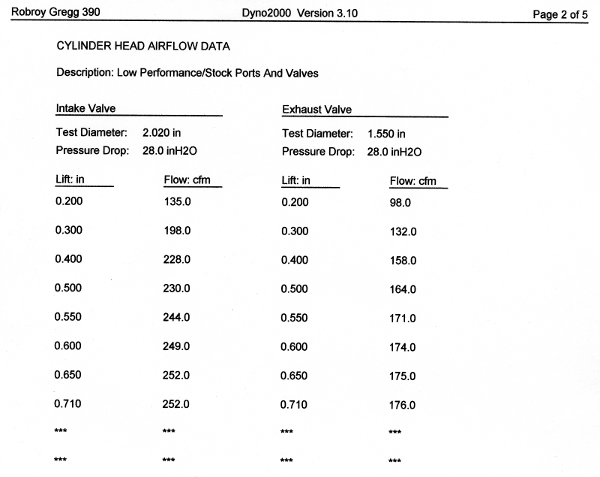

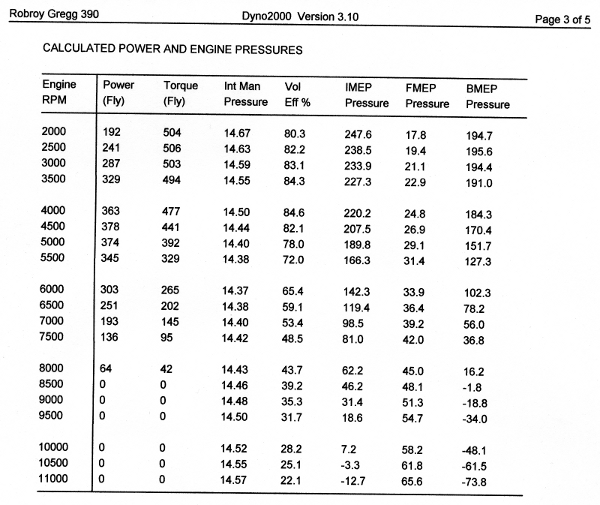

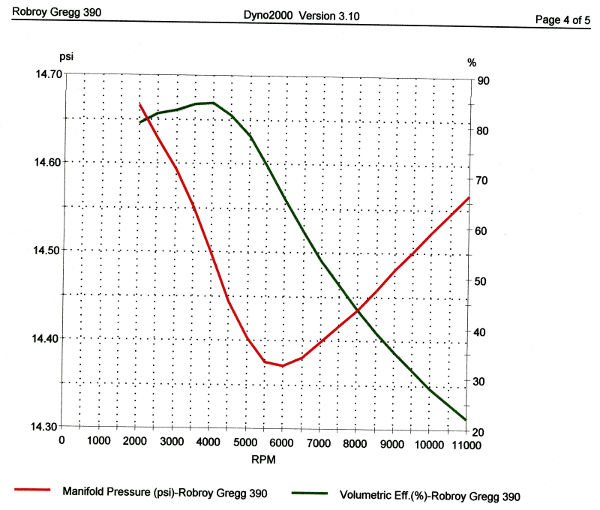

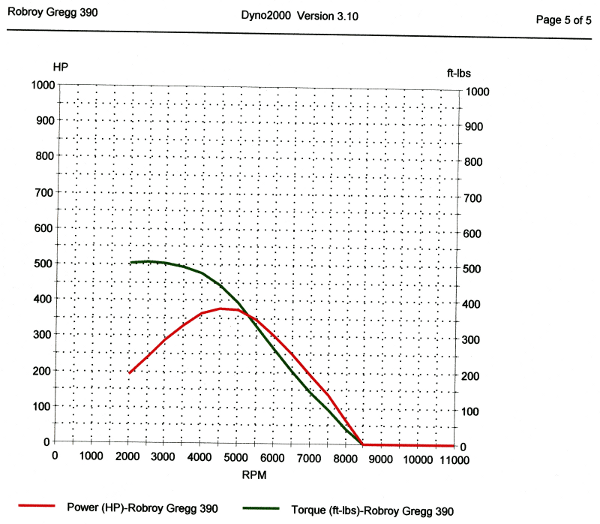

It looks to me as if Tom is using very conservative entries which in my experience is the way to go with DD2000 (and later versions, I actually think it got worse with newer versions)

I see! Excellent. From what I've heard from Tom, he does tend to make very conservative performance estimates. Even the amazing actual dyno printouts he has all over his wall were done with the engines tuned as they would be for actual driving--he didn't "doctor them up" to get those numbers.

DuckRyder wrote:robroy wrote:I should see if Tom will scan a copy of the draft invoice he wrote for me, so I can post that here too. It's detailed and itemized.

That would be interesting.

Okay doke, I'll ask for it!

DuckRyder wrote:robroy wrote:For the moment, I asked Tom to pause activity on the engine until I'd discussed its parts and specs here for a short while. Maybe y'all (there it goes again) will have some advice for me on this!

Perhaps we might, I think we all have confidence in Tom and that he will lead you in the right direction, we might offer advice for you to discuss with him. I think he (with you of course) knows what he has planned globally.

Indeed! I really appreciate the generous advice you guys have offered, and it does help me communicate more effectively with Tom--it helps to have heard about these options in advance!

DuckRyder wrote:I think it is important to remember that the F250 has a larger tire (what ~31 - ~32" diameter?) than what most of us are used to (~28") so the 3.73:1 gear won't have the same cruise characteristics as an F100 or Mustang/Torino/Fairlane/Comet/Galaxie etc, etc...

This is news to me! Thanks for pointing this out. From the small amount of experimentation I've done with RPM calculators, I have noticed what a big difference an inch or two of tire diameter can make.

I'll certainly try the truck out with its current setup for a while before making any changes. I'll probably be doing very little freeway driving for a few years anyhow, since I'll most likely be taking a route through town to work (instead of the freeway).

Last night I was reading, "How to Rebuild BIG-BLOCK FORD ENGINES," by Steve Christ, and came across this passage (page 32):

How to Rebuild BIG-BLOCK FORD ENGINES, by Steve Christ wrote:

Some 361/391 FT blocks are cast with thicker main-bearing webs and additional ribs in between. This increases their weight about 20 pounds over the FE 390. Heavier 361/391 FT blocks do not have the 352 as cast on the left front of the standard FE block. Most heavy blocks have a mirror-image 105 on the left front, though this is missing on some blocks.

And in a caption under an image of the "105" on a block (on page 33), Steve Christ says:

How to Rebuild BIG-BLOCK FORD ENGINES, by Steve Christ wrote:

In place of the 352 found on most FE blocks, many heavy-duty FT cylinder blocks have mirror image 105 on left front. In some cases, this area is left blank on heavy-duty blocks. HD blocks have additional main-bearing support and thicker main-bearing webs.

So! Does this mean I've scored with this 105 Mirror block even more significantly than I initially thought? And does this mean that I've actually got an

FT block instead of an FE?

If so, would this be more accurately called an FT engine (instead of an FE)?

FoMoCoGuy and Robert, thank you both very much for your truly excellent replies!

Robroy