What's this loud tapping sound from my new engine?

Moderator: Ranchero50

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: What's this loud tapping sound from my new engine?

Robroy, Haynes and Chiltons are 'good' for telling you what to do, terrible for telling you 'how' to do it.

Jamie

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: What's this loud tapping sound from my new engine?

'Afternoon Robert thanks for replying!

I've made these observations about the oil filter:

http://www.robroygregg.com/Number50/IMG_4414z.JPG http://www.robroygregg.com/Number50/IMG_4415z.JPG

http://www.robroygregg.com/Number50/IMG_4416z.JPG http://www.robroygregg.com/Number50/IMG_4417z.JPG

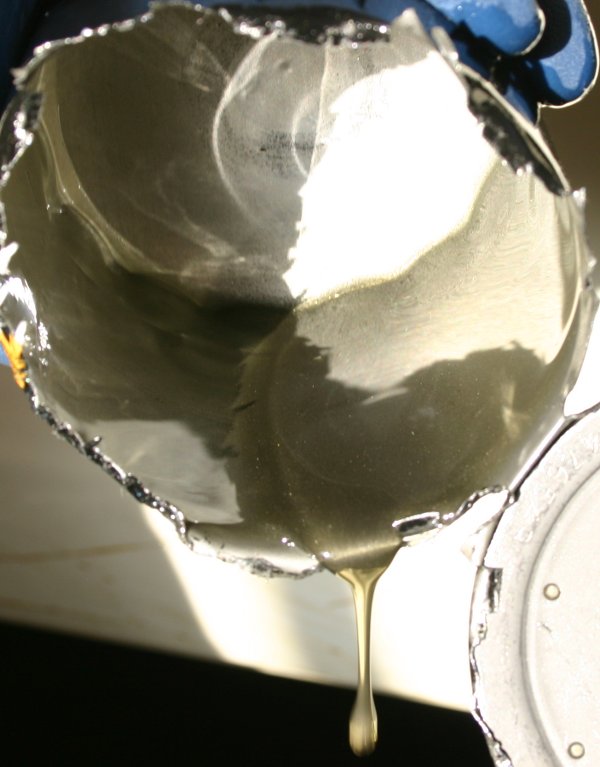

As soon as I started cutting the case off, a bunch of extra oil started dumping out. And this oil was NASTY. It was full of glitter and had a bunch of metal shards in there too. I'm not sure how well you'll be able to see it from these photos, but it's sure in there!

http://www.robroygregg.com/Number50/IMG_4422z.JPG http://www.robroygregg.com/Number50/IMG_4423z.JPG

http://www.robroygregg.com/Number50/IMG_4418z.JPG http://www.robroygregg.com/Number50/IMG_4419z.JPG

Here's the can all cracked open, at last!

http://www.robroygregg.com/Number50/IMG_4420z.JPG

The oil that was left inside the can (from outside of the filter element) was NASTY! I don't think these photos do it justice but you'll get the idea:

http://www.robroygregg.com/Number50/IMG_4424z.JPG

http://www.robroygregg.com/Number50/IMG_4427z.JPG

http://www.robroygregg.com/Number50/IMG_4428z.JPG

Now here's the oil I dumped out before taking the can apart (it came from the center of the filter element). It is perfect! The few tiny flecks you see in there are just bits of dried paint that blew in the bucket (I checked them out very closely).

http://www.robroygregg.com/Number50/IMG_4453z.JPG http://www.robroygregg.com/Number50/IMG_4457z.JPG

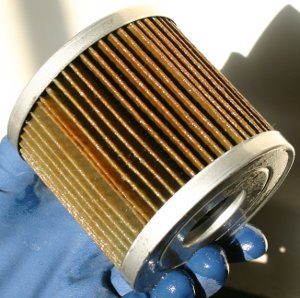

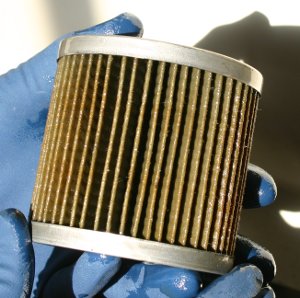

The filter element looked unhurt externally, although I can see plenty of metal flakes stuck in it!

http://www.robroygregg.com/Number50/IMG_4439z.JPG http://www.robroygregg.com/Number50/IMG_4441z.JPG

Knowing that the oil from the inside of the element looked immaculate (100% free of metal debris and glitter) makes me think that whatever I've discovered on the heads was probably not caused by my windage tray mistake.

What do ya'll think?

Also, should I slice that paper element open? And if so, would the ideal slice be parallel or perpendicular to the grooves?

Thanks very much for your generous help!

Robroy

Ah-ha! I see! That sounds a lot more doable than the entire engine. Thanks!DuckRyder wrote: 150 - 200 lbs Maybe, it is a one man and a hoist or a two man job...

You can use the hoist to slide it off the engine stand if you have to, then there is usually someone at the machine shop that will help you unload it, at least around here there is... In my experience the stand is usually about the right height that you can man handle it in and out of a truck

I've made these observations about the oil filter:

- The oil that poured out from the center of the can (from the interior of the filter, before I cracked it open) was dark, but completely free of shavings, glittery, or other debris. It looked ultra clean.

- The oil that came out from inside of the can (from the exterior of the filter) had LOTS of glitter and some metal shards in it. Mostly glitter so far. It sparkled brightly in the sun, like glittery finger nail paint (not that I know, guys).

http://www.robroygregg.com/Number50/IMG_4414z.JPG http://www.robroygregg.com/Number50/IMG_4415z.JPG

http://www.robroygregg.com/Number50/IMG_4416z.JPG http://www.robroygregg.com/Number50/IMG_4417z.JPG

As soon as I started cutting the case off, a bunch of extra oil started dumping out. And this oil was NASTY. It was full of glitter and had a bunch of metal shards in there too. I'm not sure how well you'll be able to see it from these photos, but it's sure in there!

http://www.robroygregg.com/Number50/IMG_4422z.JPG http://www.robroygregg.com/Number50/IMG_4423z.JPG

http://www.robroygregg.com/Number50/IMG_4418z.JPG http://www.robroygregg.com/Number50/IMG_4419z.JPG

Here's the can all cracked open, at last!

http://www.robroygregg.com/Number50/IMG_4420z.JPG

The oil that was left inside the can (from outside of the filter element) was NASTY! I don't think these photos do it justice but you'll get the idea:

http://www.robroygregg.com/Number50/IMG_4424z.JPG

http://www.robroygregg.com/Number50/IMG_4427z.JPG

http://www.robroygregg.com/Number50/IMG_4428z.JPG

Now here's the oil I dumped out before taking the can apart (it came from the center of the filter element). It is perfect! The few tiny flecks you see in there are just bits of dried paint that blew in the bucket (I checked them out very closely).

http://www.robroygregg.com/Number50/IMG_4453z.JPG http://www.robroygregg.com/Number50/IMG_4457z.JPG

The filter element looked unhurt externally, although I can see plenty of metal flakes stuck in it!

http://www.robroygregg.com/Number50/IMG_4439z.JPG http://www.robroygregg.com/Number50/IMG_4441z.JPG

Knowing that the oil from the inside of the element looked immaculate (100% free of metal debris and glitter) makes me think that whatever I've discovered on the heads was probably not caused by my windage tray mistake.

What do ya'll think?

Also, should I slice that paper element open? And if so, would the ideal slice be parallel or perpendicular to the grooves?

Thanks very much for your generous help!

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: What's this loud tapping sound from my new engine?

The sludge on the outside is the dirty stuff. Should be clean inside (like the oil that poured out first). At this point I wouldn't bother with the filter anymore. What's scary to ponder is all that crap came through the pump and was getting flung around inside the motor while the crank was chewing on the windage tray.

Motor teardown (start in upright position):

remove rocket shaft stand bolts to remove rockers (loosen adjuster studs first)

remove pushrods (keep in order)

remove harmonic balancer from crank

remove timing chain cover

remove timing chain (fuel pump eccentric too)

remove distributor

remove intake

remove lifters

put a long bolt in the end of the cam and remove the cam

rotate crank to get #1 piston all the way down the bore

flip motor upside down

remove #1 cylinder rod cap

tap rod / piston assy away from the crank making sure the rod bolts don't touch the crank

tap the rod piston assy all the way out the bore (catch with other hand)

repeat for other cylinders

remove main crank caps

lift crank out of block (stand on end in a corner)

That's the teardown, scary eh? Wait until you put it together, we'll have 10-20 pages of threads on that.

Personal suggestion is pull it apart yourself and clean it up, but get someone you trust to put it back together for you. Get price quptes both ways though, some shops don't like basket cases.

Jamie

Motor teardown (start in upright position):

remove rocket shaft stand bolts to remove rockers (loosen adjuster studs first)

remove pushrods (keep in order)

remove harmonic balancer from crank

remove timing chain cover

remove timing chain (fuel pump eccentric too)

remove distributor

remove intake

remove lifters

put a long bolt in the end of the cam and remove the cam

rotate crank to get #1 piston all the way down the bore

flip motor upside down

remove #1 cylinder rod cap

tap rod / piston assy away from the crank making sure the rod bolts don't touch the crank

tap the rod piston assy all the way out the bore (catch with other hand)

repeat for other cylinders

remove main crank caps

lift crank out of block (stand on end in a corner)

That's the teardown, scary eh? Wait until you put it together, we'll have 10-20 pages of threads on that.

Personal suggestion is pull it apart yourself and clean it up, but get someone you trust to put it back together for you. Get price quptes both ways though, some shops don't like basket cases.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- DuckRyder

- Moderator

- Posts: 4925

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: What's this loud tapping sound from my new engine?

That is a pretty impressive oil filter, I think the bypass probably opened and that is how the top end got metal up there, it could not have splashed/slung up there, so either it was pumped up there or there is some thing up there rubbing.

I've been giving this some thought, while I'm sure you can accomplish it, there are some nuances that are going to be hard to explain and there is really no substitute for an experienced hand, I do think you would be better off if you could at least get someone with some experience to come assist. I don't know if that is possible or not.

BTW, after you take the rod cap off, slide a piece of fuel hose over the bolts so they can't scratch the crank.

The Haynes should give you an idea of what is involved, but definitely get the Steve Christ book for the actual build. Reminds me of Dads story about the Clymer manual for the Bultaco (or it could have been a husky or a maico) any way hes removing the clutch basket from the crank the book says "remove the bolt securing the clutch basket to the crankshaft", he tries everything nothing will loosen it, ends up breaking it off. Turns the page and it has "note: this is a left hand thread". Or the time I was trying to look up the freon charge for a Volvo in a Chilton book. The entire A/C section is "Consult a qualified Air Conditioning technician", remind me why I bought this book?

Anyway...

Yeah, I wouldn't worry about doing anything else with the filter, it looks like it saved you from it being much worse, but it does appear that some got past it.

I've been giving this some thought, while I'm sure you can accomplish it, there are some nuances that are going to be hard to explain and there is really no substitute for an experienced hand, I do think you would be better off if you could at least get someone with some experience to come assist. I don't know if that is possible or not.

BTW, after you take the rod cap off, slide a piece of fuel hose over the bolts so they can't scratch the crank.

The Haynes should give you an idea of what is involved, but definitely get the Steve Christ book for the actual build. Reminds me of Dads story about the Clymer manual for the Bultaco (or it could have been a husky or a maico) any way hes removing the clutch basket from the crank the book says "remove the bolt securing the clutch basket to the crankshaft", he tries everything nothing will loosen it, ends up breaking it off. Turns the page and it has "note: this is a left hand thread". Or the time I was trying to look up the freon charge for a Volvo in a Chilton book. The entire A/C section is "Consult a qualified Air Conditioning technician", remind me why I bought this book?

Anyway...

Yeah, I wouldn't worry about doing anything else with the filter, it looks like it saved you from it being much worse, but it does appear that some got past it.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: What's this loud tapping sound from my new engine?

Hi Jamie and Robert, thanks very much for replying!

In my ignorance, it is actually not scary to me! I know that's just because of my funny, easy going attitude about tackling stuff though. Then when I actually get my hands in to it I find tremendous obstacles at every turn, usually. But by then I'm too far in to back out!

I see your point though and agree that it would be best to have an expert at least oversee the assembly process, if not do it outright.

I've heard before that the Chilton books were pretty bad and the Haynes books are fairly bad. Thankfully I stick to the factory shop manual on #50 most of the time! This Haynes engine rebuild book was given to me by my mother, if I remember correctly.

After seeing that the oil was super clean after passing through the filter, I've been re-thinking my proclamation about this big engine work. I'm still considering simply cleaning it out as well as I can and letting nature take its course.

Some reasons to clean it out and take my chances are:

If I clean it out as well as I'm able to, flush a bunch of oil changes through it, and drive it:

Thanks again for your patience and truly outstanding advice!

Robroy

I see your point! I'm just curious to know if the stuff in the heads could have already been there, before my windage tray incident. Probably not I suppose.Ranchero50 wrote:The sludge on the outside is the dirty stuff. Should be clean inside (like the oil that poured out first). At this point I wouldn't bother with the filter anymore. What's scary to ponder is all that crap came through the pump and was getting flung around inside the motor while the crank was chewing on the windage tray.

Thanks for that tear down checklist Jamie!!!Ranchero50 wrote:That's the teardown, scary eh?

In my ignorance, it is actually not scary to me! I know that's just because of my funny, easy going attitude about tackling stuff though. Then when I actually get my hands in to it I find tremendous obstacles at every turn, usually. But by then I'm too far in to back out!

This I don't doubt!Ranchero50 wrote:Wait until you put it together, we'll have 10-20 pages of threads on that.

This is an idea! By taking it apart I'd get to learn more about how it works, which would interest me. My only reservation is imagining that most engine builders wouldn't look fondly on a huge box of parts. Or at least they'd rather receive a put together, working engine to start with.Ranchero50 wrote:Personal suggestion is pull it apart yourself and clean it up, but get someone you trust to put it back together for you.

That I may do, thanks!Ranchero50 wrote:Get price quptes both ways though, some shops don't like basket cases.

You could be right, indeed.DuckRyder wrote:That is a pretty impressive oil filter, I think the bypass probably opened and that is how the top end got metal up there, it could not have splashed/slung up there, so either it was pumped up there or there is some thing up there rubbing.

I don't know of anybody who could come help me with it, but that's OK. I do know of a few guys who have build lots of engines, but they're "fast" guys. And I'm sure they'd work on the engine in a very "fast" way, if they could even understand why I'd ever crack in to an engine that still ran!DuckRyder wrote:I've been giving this some thought, while I'm sure you can accomplish it, there are some nuances that are going to be hard to explain and there is really no substitute for an experienced hand, I do think you would be better off if you could at least get someone with some experience to come assist. I don't know if that is possible or not.

I see your point though and agree that it would be best to have an expert at least oversee the assembly process, if not do it outright.

You know, it's funny that you'd mention this! Earlier today I spent thirty seconds flipping through the Haynes book, and the ONE thing I looked at was photo of the bolts with those bits of hose on them, and a paragraph about this! I guess it's an important thing to know!DuckRyder wrote:BTW, after you take the rod cap off, slide a piece of fuel hose over the bolts so they can't scratch the crank.

Yeah, that I may do. I looked at the Christ book on Amazon and it looks really excellent. I might want to have a copy of it on hand just to know more about my engine, if not to actually re-do it myself!DuckRyder wrote:The Haynes should give you an idea of what is involved, but definitely get the Steve Christ book for the actual build.

Oh my gosh! That is rich.DuckRyder wrote:Reminds me of Dads story about the Clymer manual for the Bultaco (or it could have been a husky or a maico) any way hes removing the clutch basket from the crank the book says "remove the bolt securing the clutch basket to the crankshaft", he tries everything nothing will loosen it, ends up breaking it off. Turns the page and it has "note: this is a left hand thread".

Exactly! It's classic that they'd even have the section. I guess they were afraid of "shade tree" guys letting all their R-134 or R-12 out in to the air.DuckRyder wrote:Or the time I was trying to look up the freon charge for a Volvo in a Chilton book. The entire A/C section is "Consult a qualified Air Conditioning technician", remind me why I bought this book?

I've heard before that the Chilton books were pretty bad and the Haynes books are fairly bad. Thankfully I stick to the factory shop manual on #50 most of the time! This Haynes engine rebuild book was given to me by my mother, if I remember correctly.

Indeed, that seems to be the most probable explanation for what I'm seeing.DuckRyder wrote:Yeah, I wouldn't worry about doing anything else with the filter, it looks like it saved you from it being much worse, but it does appear that some got past it.

After seeing that the oil was super clean after passing through the filter, I've been re-thinking my proclamation about this big engine work. I'm still considering simply cleaning it out as well as I can and letting nature take its course.

Some reasons to clean it out and take my chances are:

- It seems entirely possible that after cleaning it out while still in the truck, this engine will have a long, happy service life, despite what I've seen.

- On the tops of both heads, I found a grand total of two large flakes and a few smaller flakes. Most of the rest was pretty tiny. In my ignorance, that doesn't seem like a lot of metal.

- A lot of the metal I'm seeing is probably natural for a brand new engine. Granted some isn't natural, but I'm guessing that the majority of the tiny glitter bits are natural.

- I found plenty of metal in the oil pan, but very little anywhere else. Not knowing more, I'm guessing that a lot of metal either didn't get sucked in to the oil pump, or got lodged in the oil filter. The contrast between the metal quantity in the oil pan and the rest of the engine is huge.

- The time and effort required to remove the engine and re-do it seems similar to the time and effort required to pull and re-do a worn out engine (especially if I'm hiring out the machine work). So in a sense, I may as well wear it out first.

- The cost of hiring an engine builder to assemble the engine (or to do both teardown and assemble it) would be non-trivial, I'm guessing. I'll find out for sure on Monday, but I'm guessing they'd charge at least $1,500 for the work alone. Maybe I'm way off, but that just seems like a reasonable guess.

- There is a chance that, if I went to all the trouble to have the engine pulled all apart again, they'd fine very little metal in there. And the whole time, effort, and expense wouldn't have actually saved my butt in the end.

- I'd be more likely to enjoy a long engine service life.

- I may wind up with a more reliable engine.

- I'd be sure to have greater satisfaction, knowing the engine surely wasn't being unduly damaged by hard driving.

- I might have to pay for a deep, full engine rebuild with lots of new parts down the road, and be out $4,000 to $8,000 for the job. $1,500 now would be easier to swallow than $6,000 in six months!

- I'd have an opportunity to rip the thing apart and see how it works.

If I clean it out as well as I'm able to, flush a bunch of oil changes through it, and drive it:

- What's the worst that could happen? And after how many miles? (Realistically)

- What's the best that could happen?

- What is your personal, best guess as to what would actually happen?

Thanks again for your patience and truly outstanding advice!

Robroy

- 70_F100

- Moderator

- Posts: 2999

- Joined: Mon Oct 22, 2007 11:23 am

- Location: North Carolina, Kernersville

Re: What's this loud tapping sound from my new engine?

70_F100 wrote:All of the advice I've read here is good, no doubt.

I still maintain that the bearings should be checked before buttoning it up.

If there is some embedded metal, a set of bearings is VERY inexpensive insurance against ruining a crankshaft (or worse).

Again, the small amount of time and trouble to check them is, in my opinion, well worth the peace of mind that it will provide.

Just my

Wise men talk because they have something to say; fools talk because they have to say something.--Plato

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak That's SWEAT from all that HORSEPOWER!!

That's SWEAT from all that HORSEPOWER!!

Why is it that there's seldom time to fix it right the first time, but there's always time to fix it right the second time???

That's not an oil leak

-

oldschoolrods

- Preferred User

- Posts: 326

- Joined: Tue Aug 10, 2004 11:06 pm

- Location: Lancaster, Pennsylvania

Re: What's this loud tapping sound from my new engine?

Robroy, I don't have any more to add to whats been said, but what I do to keep stuff in order is make little templates out of cardboard. For example to keep pushrods in order i'll take a piece of cardboard and label it (for example passanger side #1) then go in order.

Good luck, sorry to hear about your mis-fortunes.

Good luck, sorry to hear about your mis-fortunes.

1969 Ford F250 Custom Cab 360/C6 - currently under de-construction

- fordfriend

- New Member

- Posts: 2

- Joined: Sat Nov 07, 2009 10:07 pm

- Location: Salinas, California

Re: What's this loud tapping sound from my new engine?

Great pictures robroy!

- DuckRyder

- Moderator

- Posts: 4925

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: What's this loud tapping sound from my new engine?

What's the worst that could happen? And after how many miles? (Realistically)

The bearing material is soft and particles will embed in it. If there is metal embedded it will scratch the crankshaft possibly damaging it beyond repair. Worst case it is possible it could do enough damage to grab the bearing and turn it in the rod or main cap (called spinning). If one or more bearings were to spin it could damage the block, crank or rods beyond repair. Realistically it is probably most likely it would simply lose oil pressure or start to knock, it could happen in as little as a few thousand miles.

What's the best that could happen?

It might be fine.

My guess would be that it would run and perform fine for a reasonable period of time...What is your personal, best guess as to what would actually happen?

It is very difficult to guess because it only takes one good sized particle and the crank is going to look like the oil pump...

I suppose a compromise would be to find out what procedure and spec was used on the main bearings and pull the easiest one for inspection.

The thing is the big chunks could not have pumped up there, they had to have either broken off of somewhere or been left behind during assembly, but the metal flake oil, for the most part the only way it could have gotten there is through the oiling system.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: What's this loud tapping sound from my new engine?

Usually what happens to me is I'm cranking along 2800rpm in the middle of 3 lanes of near rush hour interstate traffic miles from an exit, miles from a pull off. Moby get's stuck in the oil pump lobes, shears the oil pump drive, you hear lifters tapping and notice no oil pressure, but have to drive it a mile or two before you can get it off the highway.

Note: When you hear the crank squealing really loudly you have about 30 seconds before the hole thing comes apart...

Note: When the fresh paint on the intake is bubbling and turning colors don't touch it out of wonder...

If you are lucky (and since you are running the stronger pump drive) the roll pin will shear in the distributor gear, you lose ignition but it'll still coast off the highway.

99% sure you'll be ok, but since the chunkies have migrated up through the engine to the valve covers that there are going to be some in the lifter valley. Consider that (if my memory is working better than normal) that when the crank was hitting the windage tray that it was throwing the chunks up into the engine vs. down into the pan. Consider the pinball effect required to get chunkies up into the lifter valley and then bumped again up into the valve cover area. At the very least just for some insurance I would pull the intake and timing chain cover to expose all the places oil and trash can hide and clean everything. Still, the best way to do it is to pull the motor out of the truck so you can roll it around.

Jamie

Note: When you hear the crank squealing really loudly you have about 30 seconds before the hole thing comes apart...

Note: When the fresh paint on the intake is bubbling and turning colors don't touch it out of wonder...

If you are lucky (and since you are running the stronger pump drive) the roll pin will shear in the distributor gear, you lose ignition but it'll still coast off the highway.

99% sure you'll be ok, but since the chunkies have migrated up through the engine to the valve covers that there are going to be some in the lifter valley. Consider that (if my memory is working better than normal) that when the crank was hitting the windage tray that it was throwing the chunks up into the engine vs. down into the pan. Consider the pinball effect required to get chunkies up into the lifter valley and then bumped again up into the valve cover area. At the very least just for some insurance I would pull the intake and timing chain cover to expose all the places oil and trash can hide and clean everything. Still, the best way to do it is to pull the motor out of the truck so you can roll it around.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: What's this loud tapping sound from my new engine?

Hey 70_F100, OldSchoolRods, FordFriend, Robert, and Jamie, thanks very much for replying!

I'll add up your replies with what I hear from Steve, and what I hear from FE Specialties, then make my decision and begin on Monday. I appreciate your candid and detailed advice!

I read the Haynes book for hours last night and engine tear down looks easy and fun! Just like reading a book on participating in a Karate match. It looks easy!

I'm going to pick up a copy of the Christ book regardless of my next move. Like the Haynes book, is the Christ book also written with a home mechanic in mind? Or is it ultra dense and technical? I probably don't mind either way, but I'm curious. The Haynes book was funny because it had a section on buying wrenches, debugging alternators, and all sorts of semi-related stuff not part of engine rebuilding.

I'm hesitating mainly because I realize that the time, effort, and good amount of the money, I'd spend to pull the engine all apart now doesn't seem very dissimilar to the time, effort, and money it would take later, when the engine's worn out.

Also, I've had this thought. How often do people pull the oil pan and and valve covers from a freshly rebuilt engine that has run for ten minutes? Basically never, right? What reason would they ever have to do that, other than abundant curiosity?

So is it possible that what I'm seeing in the oil on the heads is pretty normal for a fresh engine with ten minutes of run time? Sure what I'm seeing would be really objectionable for an engine that had been around the block a few times. But for an engine with ten minutes of run time?

Thanks very much for your kind patience with my questions!

Robroy

I'll add up your replies with what I hear from Steve, and what I hear from FE Specialties, then make my decision and begin on Monday. I appreciate your candid and detailed advice!

I read the Haynes book for hours last night and engine tear down looks easy and fun! Just like reading a book on participating in a Karate match. It looks easy!

I'm going to pick up a copy of the Christ book regardless of my next move. Like the Haynes book, is the Christ book also written with a home mechanic in mind? Or is it ultra dense and technical? I probably don't mind either way, but I'm curious. The Haynes book was funny because it had a section on buying wrenches, debugging alternators, and all sorts of semi-related stuff not part of engine rebuilding.

I'm hesitating mainly because I realize that the time, effort, and good amount of the money, I'd spend to pull the engine all apart now doesn't seem very dissimilar to the time, effort, and money it would take later, when the engine's worn out.

Also, I've had this thought. How often do people pull the oil pan and and valve covers from a freshly rebuilt engine that has run for ten minutes? Basically never, right? What reason would they ever have to do that, other than abundant curiosity?

So is it possible that what I'm seeing in the oil on the heads is pretty normal for a fresh engine with ten minutes of run time? Sure what I'm seeing would be really objectionable for an engine that had been around the block a few times. But for an engine with ten minutes of run time?

Thanks very much for your kind patience with my questions!

Robroy

- DuckRyder

- Moderator

- Posts: 4925

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: What's this loud tapping sound from my new engine?

It is written with the home mechanic in mind, not nearly so basic as a Haynes book, but easy to understand. IIRC it appears to be primarily based on a rebuild for a early to mid 60's T-Bird but where other models varied it usually points it out. It does include some tuning information, but I don't recall anything about tools other than specialty tools. I'll get my copy out and refresh my memory this evening...Like the Haynes book, is the Christ book also written with a home mechanic in mind? Or is it ultra dense and technical? I probably don't mind either way, but I'm curious.

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: What's this loud tapping sound from my new engine?

Hey Robert, thanks for replying!

That sounds like a great book to have--we're lucky that it's out there for these engines! I'll order a copy from Amazon.

Thanks again,

Robroy

That sounds like a great book to have--we're lucky that it's out there for these engines! I'll order a copy from Amazon.

Thanks again,

Robroy

- Ranchero50

- Moderator

- Posts: 5799

- Joined: Wed Nov 08, 2006 7:02 pm

- Location: Maryland, Hagerstown

- Contact:

Re: What's this loud tapping sound from my new engine?

Robroy, total investment if it's just a wash up is only going to be gaskets, around $100 or so if you buy good rubber ones and not the cork jobs that leak, and cleaning stuff and fresh fluids. If bearings $120 or so more. Personally I wouldn't bother with the cam bearings and I don't think you'll have problems with the mains or rod.

You'll have that in your next set of pistons (if you ever wear this motor out).

Right now your largest expense will be time:

2-3 hrs to pull it apart, leaving the heads on

2-3 hrs to clean it up

6-8hrs to put it back together.

You're already into it for valve cover and oil pan gaskets. You'll need the intake gaskets and some Ultra RTV to put it back together regardless.

Jamie

You'll have that in your next set of pistons (if you ever wear this motor out).

Right now your largest expense will be time:

2-3 hrs to pull it apart, leaving the heads on

2-3 hrs to clean it up

6-8hrs to put it back together.

You're already into it for valve cover and oil pan gaskets. You'll need the intake gaskets and some Ultra RTV to put it back together regardless.

Jamie

'70 F-350 CS Cummins 6BT 10klb truck 64k mile Bahama Blue

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

Contact me for CNC Dome Lamp Bezels and Ash Tray pulls.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: What's this loud tapping sound from my new engine?

Jamie, thanks for your great reply!

Thanks again for your great reply Jamie!

Robroy

True, if I tackle the assembly on my own! I already have valve cover, oil pan, carburetor, and oil pump gaskets.Ranchero50 wrote:Robroy, total investment if it's just a wash up is only going to be gaskets, around $100 or so if you buy good rubber ones and not the cork jobs that leak, and cleaning stuff and fresh fluids.

That doesn't sound so bad!Ranchero50 wrote:If bearings $120 or so more.

Is it possible to test the cam bearings without removing them, by spinning the camshaft? Also, when people use the word "mains," do they mean the main bearings (the things that install between the main caps and the connecting rods)?Ranchero50 wrote:Personally I wouldn't bother with the cam bearings and I don't think you'll have problems with the mains or rod.

Yeah true--I might not wear it out for a long time.Ranchero50 wrote:You'll have that in your next set of pistons (if you ever wear this motor out).

Thanks very much for this estimate! You could be right about this.Ranchero50 wrote:Right now your largest expense will be time:

2-3 hrs to pull it apart, leaving the heads on

2-3 hrs to clean it up

6-8hrs to put it back together.

I see your point!Ranchero50 wrote:You're already into it for valve cover and oil pan gaskets. You'll need the intake gaskets and some Ultra RTV to put it back together regardless.

Thanks again for your great reply Jamie!

Robroy