390 intake swap

Moderators: Ranchero50, DuckRyder

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: 390 intake swap

I just skin the cork gasket to prevent it from absorbing oil through it's life.

We used to do that with a center punch so the manifolds would bite into the gaskets better,

We used to do that with a center punch so the manifolds would bite into the gaskets better,

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

- BobbyFord

- 100% FORDified!

- Posts: 5372

- Joined: Sun Feb 04, 2007 9:52 am

- Location: Chatsworth, California

Re: 390 intake swap

It's hard when you are working at a dealer, trying to get one car done and another one in right away. The Ultra line of Permatex silicones as well as The Right Stuff (from Permatex) require that the parts be assembled right away and not to let skin but they also recommend that the silicone be allowed to cure overnight before returning vehicle to service.

It's nice when you are working on your own stuff at home and have the opportunity to let the sealants sit overnight. I think the engine remains leak-free for a longer period of time when allowed to sit as opposed to returning to service immediately after assembly.

It's nice when you are working on your own stuff at home and have the opportunity to let the sealants sit overnight. I think the engine remains leak-free for a longer period of time when allowed to sit as opposed to returning to service immediately after assembly.

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: 390 intake swap

Very true that is where 3M Weatherstrip adhesive came in handy immediate return to service. One thing though it matters not what you use but how clean it is when you seal it up.

I keep cans of carb cleaner as my degreaser at home for sealing things.

I keep cans of carb cleaner as my degreaser at home for sealing things.

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

-

Frankenstein

- New Member

- Posts: 40

- Joined: Sat Oct 25, 2008 8:52 pm

- Location: Newcastle, WA (12 mins east of Seattle.)

Re: 390 intake swap

Well it's alive! I just have to fine tune things and I need to get off my butt and replace the radiator. I will post pics later when I get back from getting food!

-

Frankenstein

- New Member

- Posts: 40

- Joined: Sat Oct 25, 2008 8:52 pm

- Location: Newcastle, WA (12 mins east of Seattle.)

Re: 390 intake swap

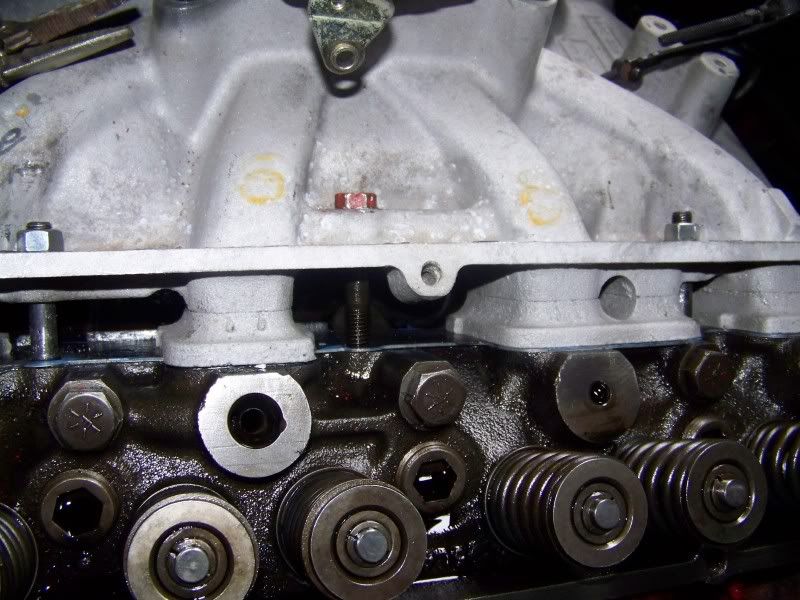

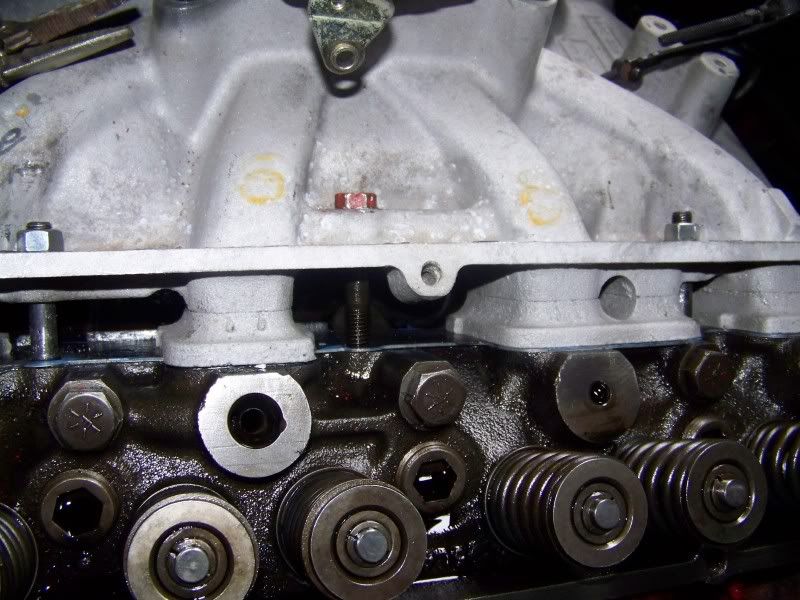

Ok, here we go! It was nice and dry when I started and now there is about 4 inches of snow on everything

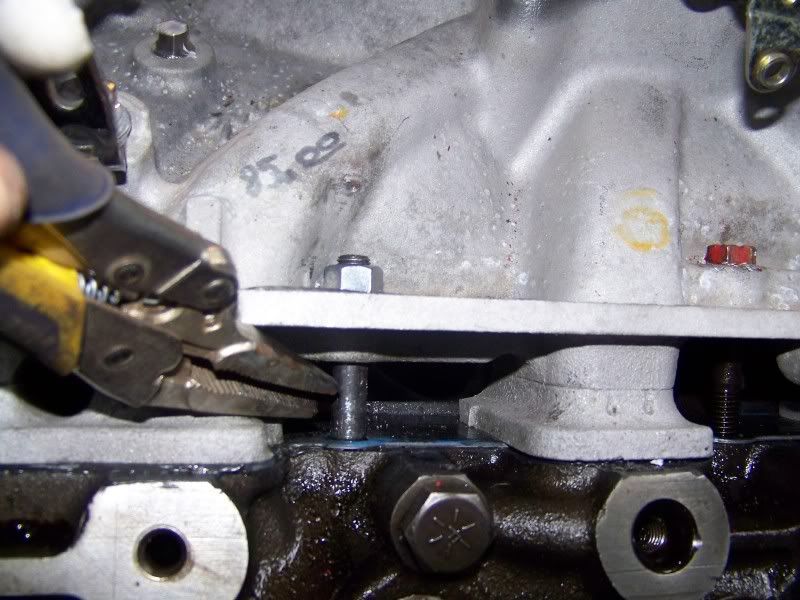

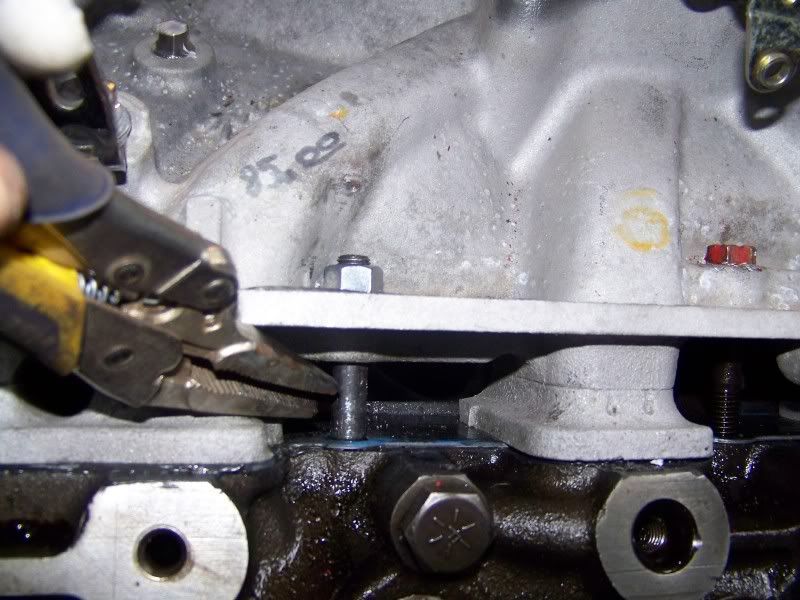

Since I didn't even think about it I set the intake without putting the 4 middle bolts in first so I raided my bolt bin and found some 3/8 studs that were about 2 3/4" long and 3/8-16 on one end and 3/8-20 on the other. I got them in finger tight then used a pair of needle nose visegrips and set them in place with some antiseaze. All intake bolts are at 18ft lbs.

so I raided my bolt bin and found some 3/8 studs that were about 2 3/4" long and 3/8-16 on one end and 3/8-20 on the other. I got them in finger tight then used a pair of needle nose visegrips and set them in place with some antiseaze. All intake bolts are at 18ft lbs.

There was no way in hell that I was going to put that P.O.S. throttle linkage rat nest back on the truck so I went to the pile and made a adjustable rod set up.

I took a strait piece of round stock, put a bend in it and threaded one end then used a piece of Lokar throttle kit that I had left over from an old toy on the threaded end.

For the pedal end I had some old linkage from a T-ram set up, ran 2 nuts about an inch apart then welded them to the other end of the round stock. My welds aren't that pretty (It's embarrassing because I'm better than that and I will beat myself up every time I look at it), I was in a hurry and just wanted the thing back together before it started snowing.

The pedal end just goes through the top hole and has about 2-3 inches of adjustment, the carb end has only about 1/4 inch adjustment but I checked the full travel of the carb and pedal and nailed it the first time so there is WOT with the pedal to the floor and.

So it starts and runs I just have to dial everything in. The 500cfm Eddy works just fine so the it will stay where it is, Im not going to bother putting on a 600 or 650 there is no point. This is a daily driver for my wife until her 48 is done.

This is the new/old problem that I'm dealing with, I did a ghetto J.B. Weld fix on the exhaust leak that held for about 3-4 weeks before it cracked out. I don't want to pull the motor or heads just to drill and tap the holes when all the bolts bust off in the heads.

Anyone know of a good epoxy or some sort of goop that will withstand the heat and still be rock hard so I can just smear it on and seal it up?

Since I didn't even think about it I set the intake without putting the 4 middle bolts in first

There was no way in hell that I was going to put that P.O.S. throttle linkage rat nest back on the truck so I went to the pile and made a adjustable rod set up.

I took a strait piece of round stock, put a bend in it and threaded one end then used a piece of Lokar throttle kit that I had left over from an old toy on the threaded end.

For the pedal end I had some old linkage from a T-ram set up, ran 2 nuts about an inch apart then welded them to the other end of the round stock. My welds aren't that pretty (It's embarrassing because I'm better than that and I will beat myself up every time I look at it), I was in a hurry and just wanted the thing back together before it started snowing.

The pedal end just goes through the top hole and has about 2-3 inches of adjustment, the carb end has only about 1/4 inch adjustment but I checked the full travel of the carb and pedal and nailed it the first time so there is WOT with the pedal to the floor and.

So it starts and runs I just have to dial everything in. The 500cfm Eddy works just fine so the it will stay where it is, Im not going to bother putting on a 600 or 650 there is no point. This is a daily driver for my wife until her 48 is done.

This is the new/old problem that I'm dealing with, I did a ghetto J.B. Weld fix on the exhaust leak that held for about 3-4 weeks before it cracked out. I don't want to pull the motor or heads just to drill and tap the holes when all the bolts bust off in the heads.

Anyone know of a good epoxy or some sort of goop that will withstand the heat and still be rock hard so I can just smear it on and seal it up?

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: 390 intake swap

Looks Great

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

- SteveC

- Blue Oval Guru

- Posts: 1091

- Joined: Mon Oct 29, 2007 11:04 pm

- Location: Nebraska, North Platte

- Contact:

Re: 390 intake swap

looks good... i did something simular to my 67's i tried using the factory trapezze set up and foudn that it wouldnt work for the 600cfm holly so i put something like that on mine with a few return springs and it works great

I don't really care about brands Chevy Ford Dodge ...as long as it doesn't sound like two old dudes farting in a coffee can.

http://s169.photobucket.com/albums/u223/imabaka70/ Projects listed on the left side

WOOOT!! i passed my mechanics classes. Now working as a mechanic and waiting to go for my ASE certifications.

1967 f-100 4x4

1969/72 f100 351w EFI m5r2 5 speed

1988 ford f150 xlt lariat

1961 VW Beetle (wifes car)

http://s169.photobucket.com/albums/u223/imabaka70/ Projects listed on the left side

WOOOT!! i passed my mechanics classes. Now working as a mechanic and waiting to go for my ASE certifications.

1967 f-100 4x4

1969/72 f100 351w EFI m5r2 5 speed

1988 ford f150 xlt lariat

1961 VW Beetle (wifes car)

- Dragon

- 100% FORDified!

- Posts: 2659

- Joined: Sat Feb 16, 2008 4:43 pm

- Location: Albuquerque, New Mexico

- Contact:

Re: 390 intake swap

First thing I do is throw that trapeze away and just use a long rod with ball ends on it.

Old Fords Rule

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

Was a Ford Service Tech

71 F250 with Shell Car 390 NP435 Dana 60 3.73s, PS, PB, 750 EC VS Holley Accel Points Eliminator.

98 Volvo S70 2.4T Auto

71 Service manuals Volumes 1,2,3 and 4 So ask away.

My Gallery

Spark test

- dablack00

- Blue Oval Fan

- Posts: 695

- Joined: Wed Jan 12, 2005 7:32 am

- Location: Texas, Lufkin

Re: 390 intake swap

I found that the trapeze works great for the stock intake and carb, but once you go aftermarket don't try and rig it up. Just got with ball ends on a threaded rod. I picked up my parts form summit and mcmastercarr. I have tons of adjustment and no slop.

Now, will someone please send this guy an extra PS pump dip stick? Come one. I know you guys have two or three of them somewhere.

Now, will someone please send this guy an extra PS pump dip stick? Come one. I know you guys have two or three of them somewhere.

-

Frankenstein

- New Member

- Posts: 40

- Joined: Sat Oct 25, 2008 8:52 pm

- Location: Newcastle, WA (12 mins east of Seattle.)

Re: 390 intake swap

LOL, yeah I need a new dipstick pretty bad but I need a radiator even more.

-

fordman

- 100% FORDified!

- Posts: 22329

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: 390 intake swap

that rod looks like the one i have here that someone made. they welded it just like you did yours. what is wrong with your dipstick. other than its blue and the engine is red.

-

Frankenstein

- New Member

- Posts: 40

- Joined: Sat Oct 25, 2008 8:52 pm

- Location: Newcastle, WA (12 mins east of Seattle.)

Re: 390 intake swap

He was talking about my power steering dipstick, the handle is busted off. I may just weld a new handle on it or make a whole new one out of an old chevy dipstick.

- dablack00

- Blue Oval Fan

- Posts: 695

- Joined: Wed Jan 12, 2005 7:32 am

- Location: Texas, Lufkin

Re: 390 intake swap

NOOOOOOOO!!!!!!!!!!!!! That cheby dipstick won't work right so close to the distributor. They aren't used to that!Frankenstein wrote:I may just weld a new handle on it or make a whole new one out of an old chevy dipstick.

-

fordman

- 100% FORDified!

- Posts: 22329

- Joined: Sun Aug 28, 2005 8:17 pm

- Location: Kansas, Ottawa

- Contact:

Re: 390 intake swap

oh ok i finally see it now. dialup takes some time to get all the pics in one thread at one time.

-

Frankenstein

- New Member

- Posts: 40

- Joined: Sat Oct 25, 2008 8:52 pm

- Location: Newcastle, WA (12 mins east of Seattle.)

Re: 390 intake swap

WOW, talk about lost power!!! I got it all dialed in pretty good along with getting the exhaust leak patched up with some 2000* Putty from Granger http://www.grainger.com/Grainger/items/2TKR6 (thanks Dragon)

I still have to rejet the carb because I had it set for a slant six and I may or may not fab up a kickdown rod that will work with the Eddy carb, it is my wifes daily driver and she only goes on the freeway for 2 miles so I don't think that she needs the passing gear. I was going to get the Accell points eliminator kit at the local parts store but the closed it down because of the 3 feet of water that was flowing through it the other day.

The only thing that isn't working is the temp gauge. I was in 3 cars before the truck so I think that it finally kicked the bucket.

Thanks for all your help guys!!!!

I still have to rejet the carb because I had it set for a slant six and I may or may not fab up a kickdown rod that will work with the Eddy carb, it is my wifes daily driver and she only goes on the freeway for 2 miles so I don't think that she needs the passing gear. I was going to get the Accell points eliminator kit at the local parts store but the closed it down because of the 3 feet of water that was flowing through it the other day.

The only thing that isn't working is the temp gauge. I was in 3 cars before the truck so I think that it finally kicked the bucket.

Thanks for all your help guys!!!!